Premium Print on Demand Products: Superior Quality Manufacturing

Premium print on demand is not an accident. It is the outcome of disciplined manufacturing choices, rigorous quality control, smart vendor selection, and an unflinching focus on customer experience from mockup to unboxing. As a mentor who has audited countless POD catalogs and sampled from the usual suspects across the US and Europe, I can tell you that the difference between “fine” and “premium” is rarely a single decision. It is a system. In this guide, I will show you how to build that system, drawing on first‑hand lessons and reputable sources from across the POD ecosystem.

What “Premium” Means in POD Today

Print on demand is a dropshipping model where products are produced after purchase and shipped directly to the customer by a third party. That definition is simple; delivering premium results is not. Premium means consistent print resolution, faithful color, durable materials, clean finishing, reliable shipping, and a return experience that customers trust. It also means designing for the manufacturing reality rather than against it.

The fundamentals are well known across the best industry guides. Shopify’s own overview underscores the benefits of on‑demand production for cash flow and testing, but it warns that per‑unit costs are higher than bulk orders and that you have less control over shipping. Fourthwall’s resources add that merchants can pass through the true carrier cost to buyers with dynamic rates, typically seeing delivery windows around five to eight days for most items, which is competitive when expectations are set correctly. Market growth remains a key tailwind: sources cited by AutoDS and Peaprint reference Grand View Research, Statista, and IMARC, with forecasts in the neighborhood of strong double‑digit annual growth and tens of billions of dollars by the early 2030s. You do not have to chase every product to build a premium line; you only need a selection that your audience genuinely values, executed with consistency they will pay for.

The Manufacturing Methods That Define Quality

The print method you choose determines the ceiling for color, hand feel, durability, and detail. Fourthwall’s knowledge base and other trade sources offer a clear view of the major methods in use.

Direct‑to‑Garment (DTG)

DTG on cotton apparel excels at speed, full‑color artwork, and a “printed into the fabric” feel. It shines for on‑demand operations, especially for smaller creators. It does not print on seams, and typical printable areas land around 16 in by 12 in on the front or back. Expect slightly less vibrant colors than a great screen print, and be aware of a practical nuance Fourthwall calls out: bright white designs on deep black garments may look slightly faded unless you are deliberately styling for that effect.

Screen Printing

The MOQ workhorse for premium tees and hoodies remains screen printing. Fourthwall notes this is the highest quality look you are used to seeing in retailers, with unmatched vibrancy, exceptional hand feel when executed well, and outstanding durability. The trade‑offs are setup cost, per‑color fees, and the requirement to hit minimums to make unit economics sensible. If you are running drops or have the demand to batch, this method sets a high bar for print quality.

Sublimation and Cut‑and‑Sew

Full‑dye sublimation enables all‑over prints that cover every panel, often requiring polyester‑heavy fabrics for best results. It can be delivered with no minimums by some vendors but usually at higher cost and with occasional alignment quirks. A cut‑and‑sew workflow dyes or sublimates panels separately and then stitches them together, often improving alignment across seams relative to whole‑garment sublimation. It is still an expensive track and works best when your design requires true seam‑to‑seam storytelling.

Embroidery

Embroidery adds premium perceived value on hats, hoodies, and accessories. It costs more per unit than DTG but scales favorably at higher volumes. When the design offers clean lines, limited color changes, and a placement that does not compromise comfort, embroidery can be the fastest path to a premium feel without perfecting complex print files.

Method | Best For | Look and Feel | Color Capability | Constraints | Notes |

|---|---|---|---|---|---|

DTG | On‑demand apparel, full color | Soft, flush with fabric | Unlimited colors | No seams, typical 16×12 in area | White on black can look faded, per Fourthwall |

Screen Printing | High‑volume tees/hoodies | Crisp, vibrant, durable | Block colors only | Setup fees, per‑color costs, no seams | Retail‑grade finish when well executed |

Sublimation | All‑over prints | Seam‑to‑seam coverage | Excellent on synthetics | Polyester blends preferred | Some items offered without minimums at higher cost |

Cut‑and‑Sew | Precision all‑over layouts | Better seam alignment | As per sublimation | Higher cost, longer lead | Strong for pattern‑heavy designs |

Embroidery | Caps, polos, hoodies | Premium texture | Limited per stitch | Density and small detail constraints | Elevates perceived value quickly |

On‑Demand vs MOQ: Choosing the Right Production Track

You do not earn a premium reputation by overpromising or by forcing a production method to do what it cannot. Fourthwall’s platform guidance separates two realities: on‑demand printing, which has no minimums and is ideal for growing catalogs, and minimum order quantity (MOQ) production, which triggers only when orders hit a floor. On‑demand DTG and embroidery let you move quickly with low risk. MOQ unlocks screen printing, cut‑and‑sew, and some variants of full‑dye sublimation that provide top‑tier color and construction, but only when demand justifies the batch.

The risk calculus is straightforward. If you fail to reach the minimum, you will miss delivery and damage trust. If you plan demand, coordinate launches, and price properly, you unlock better unit economics and methods that often outperform on touch and vibrancy. Many premium brands find success with a hybrid approach: evergreen on‑demand staples that anchor the store and occasional, tightly executed drops that use MOQ methods to create urgency and deliver special textures and finishes.

Quality Control That Separates Great from Good

When you audit disappointed customers, the same five quality dimensions recur: print resolution, color accuracy, material quality, durability, and service responsiveness. Qikink’s review of Amazon POD stresses these fundamentals, and in my experience they apply regardless of platform. Gelato’s quality checklist is equally pragmatic: prepare files correctly, proof before production, conduct press checks, monitor color, verify registration, confirm paper or material quality, check finishing, and perform a final inspection before packing.

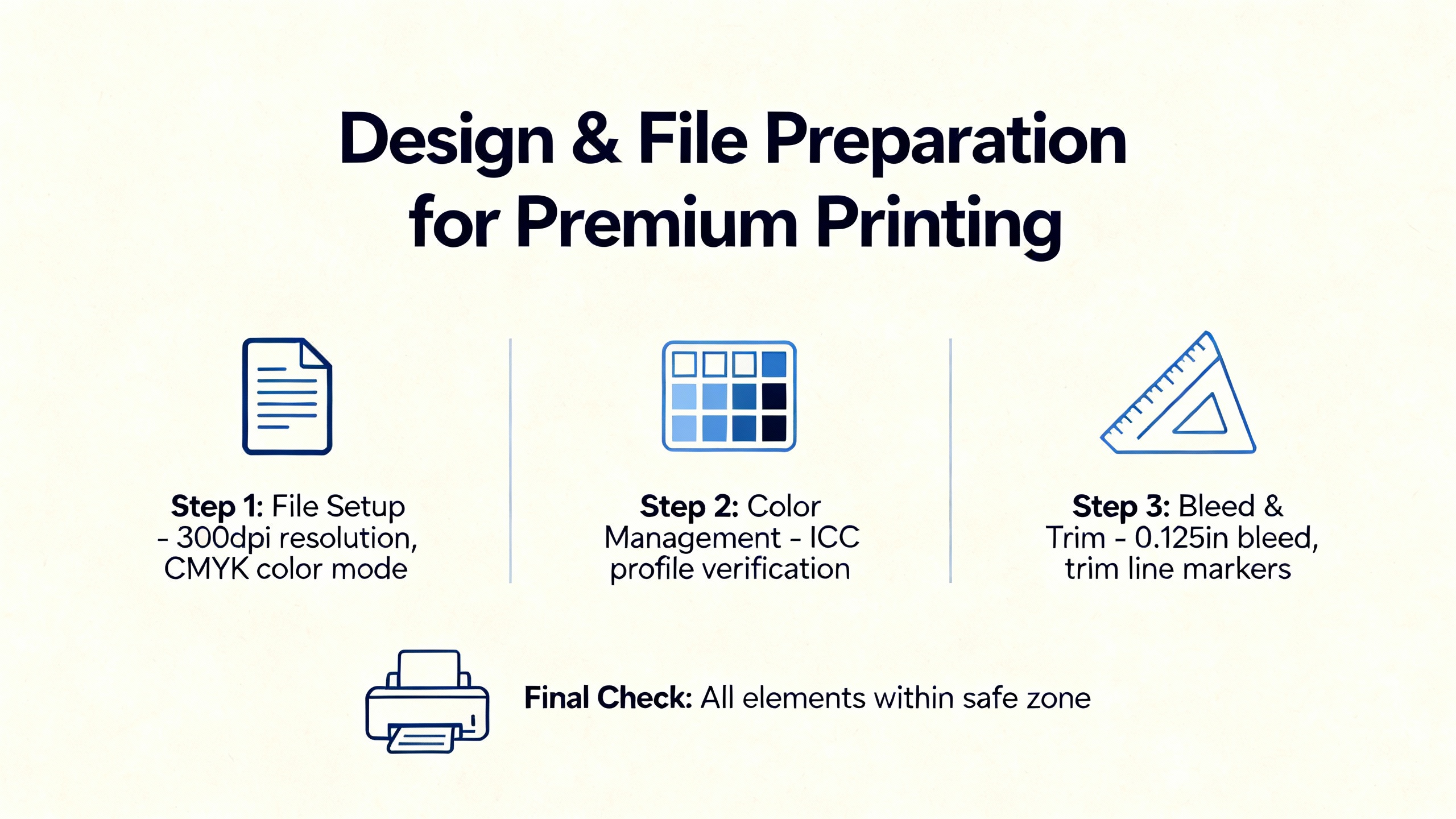

Paper goods and book‑like products add another layer. AuthorImprints documents manufacturing tolerances common to digital presses, such as trim and registration variance around 0.125 in, and the importance of file preparation that respects reality. Supply 300 ppi images at final size, embed and flatten fonts, provide at least 0.125 in bleed, and keep critical text a safe 0.25 to 0.5 in inside the trim. Avoid hairline rules thinner than about 0.5 pt, and prefer 100% K for body text to reduce show‑through. While these examples are from book printing, the principles translate to posters, cards, and wall art in POD catalogs.

Scoredetect’s supplier guide notes that even major platforms allow print variance around 1/8 in. The point of a premium operation is not to demand perfection beyond the process; it is to design, proof, and message within those tolerances. That is how you deliver results that feel intentional rather than accidental.

Stage | Premium Checks That Matter | Practical Details |

|---|---|---|

Pre‑print | File prep and proofing | 300 ppi at final size, correct color profiles, bleed added, safe margins respected; review digital or hardcopy proofs |

In‑print | Press checks and color control | Verify the first units against proofs; monitor alignment and color drift during the run |

Post‑print | Finishing, packaging, and final inspection | Confirm cutting, binding, or trimming quality; protect surfaces; inspect before shipping and correct issues |

Some operators share quantitative claims about QC return on investment. GetFuel highlights that most customers cite print quality as the driver of repeat orders and argues that testing can slash complaints and boost repeat business. Regardless of the exact percentages, the commercial logic is sound: the fastest way to premium is a rigorous sampling and QA habit that never gets skipped, especially during seasonal surges.

Choosing a Supplier Capable of Premium Manufacturing

Platform choice is not a religion; it is a supply chain decision. The best vendors for premium results share a few traits. They provide strong print quality and materials, reliable shipping, real support, and clear technical documentation. Printseekers emphasizes ordering samples, testing integrations, and validating fulfillment speed. Scoredetect’s buyer’s guide adds practical comparisons: some networks produce most orders within two days, others average a few days for production plus common US transit times. Fourthwall passes through true carrier costs with dynamic rates, which is appealing when you want price transparency and to optimize delivery windows for fans in specific regions.

Branding options also matter. Scoredetect calls out white‑label packaging, branded packing slips and tracking pages, and garment labels as differentiators. Amazon Merch on Demand’s resource hub is explicit about using official product templates, adhering to content policies, and reading best practices before listing, which is exactly the kind of operational rigor premium brands embrace.

Criterion | What to Verify | Indicators of a Premium‑Ready Partner | Publisher Notes |

|---|---|---|---|

Print quality | Samples across SKUs | Sharp detail, accurate color, minimal defects, consistent hand feel | Qikink, Printseekers |

Materials | Blank brand and fabric | Soft hand feel, weight aligned to product story, ethical options | Fourthwall, Printseekers |

File support | Templates and specs | Clear print areas, DPI guidance, color profile instructions | Amazon Merch on Demand resources, Shopify |

Shipping | Production times and carriers | Predictable production windows; delivery estimates with tracking | Scoredetect, Fourthwall, Printseekers |

Branding | Packaging and labels | Branded slips, labels, inserts, white‑label packaging | Scoredetect |

Integrations | Storefront and automation | Native connectors, inventory sync, auto‑fulfillment, real‑time tracking | Scoredetect, Printseekers |

Support | Responsiveness and escalation | Fast replies, clear RMA flow, proactive issue resolution | Qikink, Printseekers |

Catalog Strategy for Premium Brands

A premium catalog is not a long catalog; it is a coherent one. Awkward Styles recommends aligning product types with audience needs and using accessories and home décor to complement apparel. Shopify’s guide lists bestselling categories like T‑shirts, mugs, posters, all‑over‑print hoodies and leggings, and personalized gifts, and it highlights that using lifestyle imagery and on‑brand mockups materially improves conversion. DynamicMockups and other creators remind us that high‑quality mockups are not a vanity item; they are a trust signal.

Printful’s editorial on common mistakes opens with the most expensive misstep of all: designing without a defined audience. In practice, that single error creates a cascade of bad choices from color palettes to product types and pricing. Start with a niche you understand, then select products and printing methods that fit that niche’s preferences and willingness to pay. Peaprint and Shopify both recommend ordering samples and iterating continuously; that is where premium brands are born.

Pricing, Margins, and the Economics of Quality

Premium quality must be profitable to be sustainable. GetFuel suggests modeling total landed cost, including platform fees, payment processing, shipping, marketing, and taxes, then targeting margins that can fund growth. A practical reality is that some categories carry higher base prices, but that does not preclude strong margins if the perceived value is higher as well. AutoDS notes typical base price ranges for common items and recommends higher targets on complex products like footwear.

Product (Base) | Typical Base Price Range | Premium Pricing Strategy |

|---|---|---|

Mug | 10.00 | Elevate with material and finish; bundle with giftable items |

Unisex T‑shirt | 9.75 | Offer design depth and fit clarity; premium blanks for higher AOV |

Hoodie | 19.00 | Position as staple; add embroidery or screen print for premium tiers |

Phone case | 9.50 | Lean on patterns and personalization; sell as add‑on |

Poster | 8.00 | Use 300 ppi art; frame or mount upsells increase margin |

Tote bag | 15.99 | Promote as reusable, durable accessory; pair with apparel |

Tumbler | 16.99 | Use lifestyle content; upsell seasonal or event editions |

GetFuel frames typical POD margins in the range many merchants see and suggests aiming for at least 20% profit per item, while AutoDS recommends targeting 40% or more on higher‑ticket items like footwear due to complexity and returns risk. Both perspectives converge on a single point: premium requires enough gross profit to absorb returns, reships, and samples without starving your marketing.

Design and File Preparation that Print Premium

Great manufacturing will not rescue poor file prep. Shopify’s guidance for creators and AuthorImprints’ technical notes align on a few non‑negotiables. Provide 300 ppi artwork at the final print size and use the correct formats for the method, such as transparent PNG for DTG. Respect the printable area and avoid tiny type or thin lines that do not survive at scale. For paper goods like posters, add at least 0.125 in of bleed and keep critical content 0.25 to 0.5 in inside the trim edge. For apparel, heed method‑specific templates and consider color interactions; as Fourthwall observes, heavy white on black with DTG can look desaturated compared with screen printing.

Finally, design for the material. Sublimation on a polyester‑heavy hoodie carries color differently than DTG on ringspun cotton. Embroidery distorts very small type or dense fills. The premium mindset is to design with the substrate and method in mind, not to fight them.

Sampling, Mockups, and Launch Cadence

Sampling is not optional for premium brands. Printseekers emphasizes that most partners who accept free samples choose to work with them afterward, a reminder of how decisive a real sample can be. Shopify notes that some platforms offer sample discounts, and those dollars are well spent when they prevent bad reviews and returns.

Mockups deserve the same discipline. DynamicMockups and similar tools demonstrate how fast you can produce a wide set of realistic visuals, but speed should not trump authenticity. Use mockups that match your actual fabric and print method, shoot your own lifestyle photos as soon as samples arrive, and keep your catalog visually coherent. Refreshing designs two to four times per year is a healthy cadence for most brands. Align launches to seasons and US holidays. Fourthwall’s team advises planning a month or more ahead of Black Friday and warns that orders placed after the first week of December may not make it by Christmas, particularly when supply chains and carriers are under pressure. Premium brands set those expectations clearly on the product page and the shipping FAQ.

Shipping, Delivery, and Regionalization

Shipping is part of product quality. Scoredetect compiles several helpful benchmarks: SPOD produces most orders within roughly 48 hours, Printful commonly runs two to five days of production plus three to four days for US shipping, and Printify’s local production can take two to three days depending on the partner. Fourthwall’s resources describe dynamic shipping rates with pass‑through carrier pricing and typical five to eight day delivery windows for many items. Printseekers cites two to seven day shipping depending on the destination once an item is produced.

The lesson is not to promise the fastest across the board; it is to choose products fulfilled close to your audience and to publish realistic windows. Fourthwall even recommends choosing SKUs fulfilled in your target regions, which lowers cost and shortens delivery. That is how premium brands protect the unboxing moment.

Provider or Model | Production Target | Typical US Delivery Timing | Notes |

|---|---|---|---|

SPOD | Most orders within about 48 hours | Add transit based on carrier | Scoredetect |

Printful | Two to five days production | Three to four days transit | Scoredetect |

Printify network | Around two to three days production | Varies by partner and region | Scoredetect |

Fourthwall (general) | On‑demand, dynamic rates | Commonly five to eight days total | Fourthwall |

Printseekers | Dependent on SKU | Around two to seven days shipping | Printseekers |

Care Instructions that Protect Prints

Your care guidance is a lever for quality perception and longevity. For apparel, I recommend washing inside‑out on cold, avoiding harsh chemicals, and tumble drying low or air drying to reduce heat‑related degradation. Advise customers to avoid ironing directly on prints and to follow any care label on the blank garment. For wall art and paper goods, suggest clean, dry handling; protect from prolonged direct sunlight; and use frames or sleeves that match the material. You do not need a novel to communicate these points—just a concise care card in the package and a care section on the product page.

Buying Tips for Premium‑Minded Sellers

If you want premium output, start by narrowing your niche and anchoring your assortment around two or three hero products. Order physical samples from at least two providers and compare print sharpness, color fidelity, material hand feel, and finishing. Price after you know your real landed cost, including payment, shipping, and marketing. Use Shopify’s and Amazon’s official templates to avoid technical rejections, and follow the best‑practice documentation from your chosen vendor. Finally, instrument your store to measure conversion, returns, and repeat purchases. The fastest way to a premium reputation is a feedback loop that never rests.

Short FAQ

What makes a print on demand product feel premium to customers? Customers experience quality through their senses and through reliability. Crisp print edges, accurate colors, soft and durable materials, and a clean hand feel matter. So do predictable delivery windows, protective packaging, and a simple return path. When all of those show up together, price resistance falls.

Is MOQ worth it for a premium brand? MOQ is worth it when your design and audience demand the strengths of screen printing or cut‑and‑sew and you can reliably hit the minimums. Many premium brands run a hybrid model: evergreen on‑demand staples plus limited MOQ drops to deliver special finishes and higher perceived value.

How should I time holiday launches in the US? Plan at least a month before Black Friday and set realistic cutoffs for Christmas delivery, as Fourthwall’s guidance suggests. Factor in production and transit, build a buffer, and display cutoff dates prominently on product and cart pages.

Closing

Premium print on demand is a system, not a slogan. Choose the right method for the job, enforce quality at every stage, select suppliers that can keep their promises, and design your catalog around what your audience actually values. The market tailwinds are real, but they reward operational discipline most of all. If you want help building your premium system from samples to seasonal planning, I’m here to mentor you through it.

References

- https://www.gcu.edu/blog/performing-arts-digital-arts/how-start-print-demand-business-designer

- https://digital.lib.washington.edu/bitstreams/440a75ce-7b0d-4390-ac0a-aefbcaf4380c/download

- https://admisiones.unicah.edu/virtual-library/8soAv3/1OK033/print-on_demand_business__plan.pdf

- https://fourthwall.com/design-and-sell

- https://merch.amazon.com/resource/201849250

- https://www.authorimprints.com/pod-print-quality-problem-examples/

- https://www.getfuelpod.com/post/common-print-on-demand-mistakes-and-their-solutions

- https://peaprint.com/blog/a-complete-guide-about-print-on-demand-you-need-to-know

- https://www.printful.com/blog/print-on-demand-mistakes

- https://www.printseekers.com/blog-post/8-tips-on-how-to-choose-a-print-on-demand-supplier-for-a-successful-e-commerce-store