Scratch Proof Personalized Tumbler: Resilient Drinkware Solutions

As a mentor to on‑demand printing entrepreneurs, I spend a lot of time in the weeds with founders launching personalized tumblers for corporate gifting, retail drops, and DTC storefronts. The number one product complaint I help them eliminate is cosmetic wear: coatings that scuff during fulfillment, lids that cloud in the dishwasher, and logos that fade after a season of use. A “scratch‑proof” pitch is enticing, but in practice the winning strategy is a stack of choices—material, finish, personalization method, lid engineering, packaging, and after‑care—that together produce a scratch‑resistant, resilient experience customers trust and re‑order. This guide distills what the material science and third‑party testing shows, and turns it into a practical blueprint your team can execute.

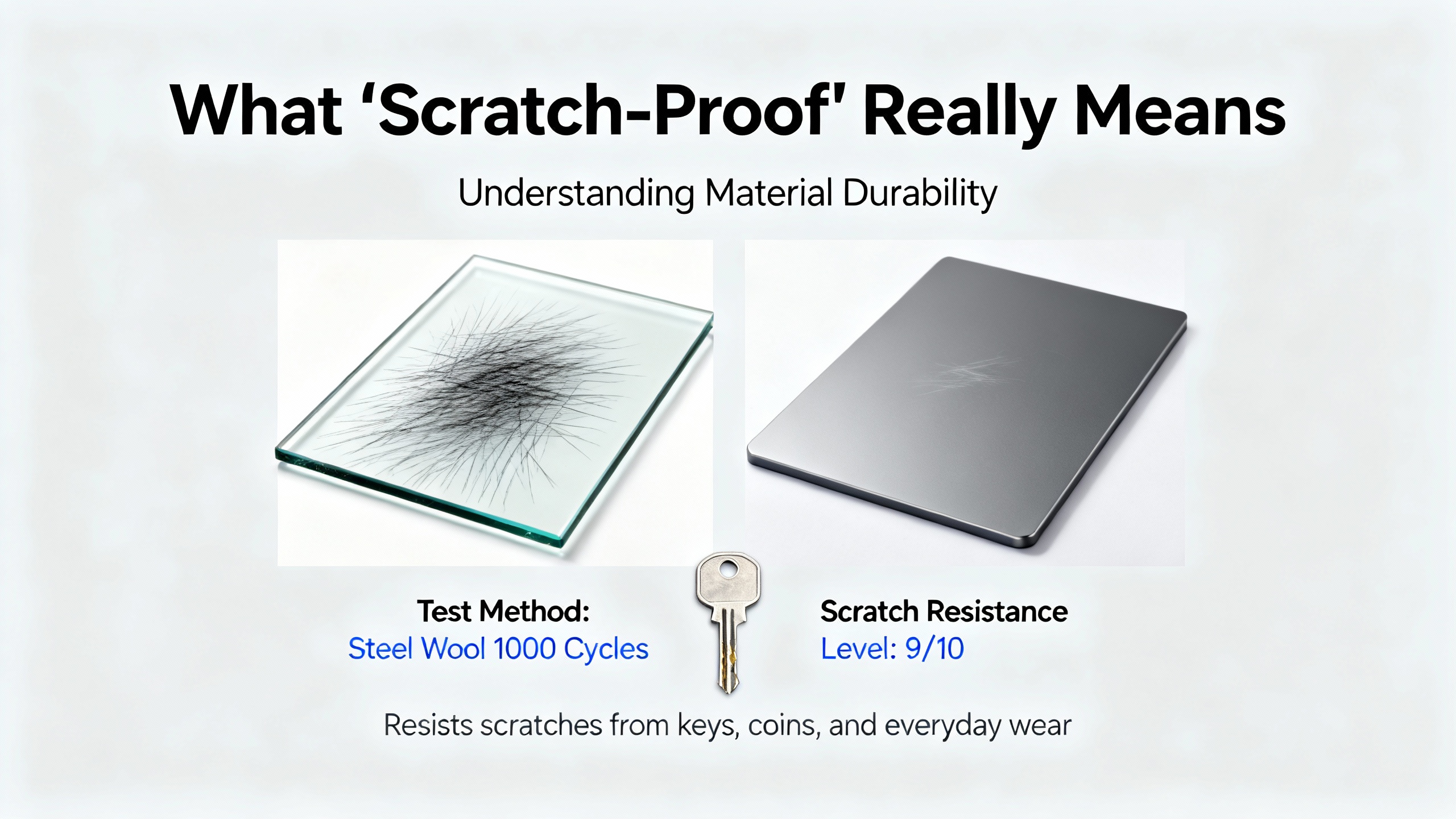

What “Scratch‑Proof” Really Means

In drinkware, nothing is literally scratch‑proof. Serious brands and retailers frame durability as scratch‑resistant, chip‑resistant, or shatter‑resistant under normal use. That phrasing is not marketing hedging; it reflects how materials behave in real life. Durable polymers like Tritan and SAN, metal shells like 18/8 stainless steel, and tempered or chemically strengthened glass all handle abrasion, drops, and repeated washing differently. Sources focused on unbreakable and scratch‑resistant drinkware, including Rowdy Crowd, Sur La Table, and Wirecutter, consistently show that the best outcomes come from matching the substrate and surface finish to the use case, then setting accurate expectations about care and longevity. For personalized tumblers, that means pairing an abrasion‑resistant coating with a marking process that does not become the weak link.

The Material Science of Durable Tumblers

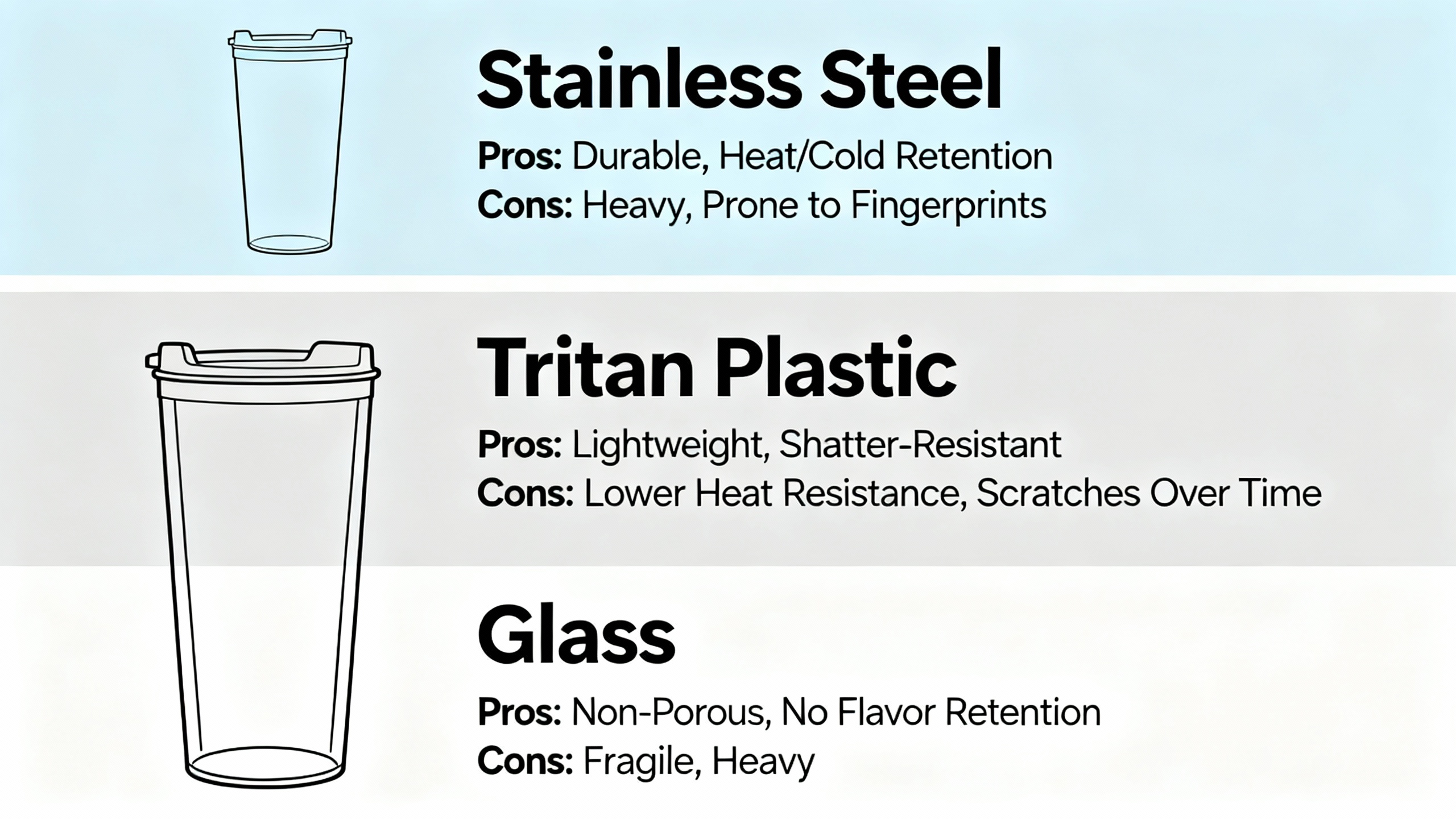

Stainless Steel 18/8: The Workhorse for POD Branding

For on‑the‑go, leak‑managed, temperature‑controlled tumblers, stainless steel remains the top performer. Food‑grade 304 stainless (18/8 chromium–nickel) is prized for corrosion resistance and overall durability, with chromium helping prevent rust and nickel improving corrosion resistance, as described by the Greens Steel team. When combined with double‑wall vacuum insulation, stainless steel tumblers deliver the longest hot and cold retention ranges in mainstream use while tolerating daily knocks in cars and backpacks. AFLOAT’s 22 oz Bison Tumbler illustrates a sensible spec for mobility: heavy‑duty steel construction, a leak‑resistant lid, and a powder‑coated exterior that improves grip and helps the shell resist superficial scratches. Brand and review sources such as Giraffyco and JollyChef show typical vacuum performance ranging from about 5 to 8 hours hot and 10 to 16 hours cold in everyday sizes, with best‑in‑class large formats claiming up to a full day cold when lids stay closed. Stainless is opaque, so color and artwork come from paint, powder coats, or applied inks rather than the base material itself, which makes finish selection and curing a core decision for scratch resistance.

High‑Performance Plastics: Tritan, Polycarbonate, and SAN

Demand for “unbreakable” drinkware led to strong plastics with very different trade‑offs. Simply Smart Living’s long‑form breakdown is particularly useful for procurement teams. Tritan is BPA‑free, glass‑clear, dishwasher‑safe, and outstanding at impact and thermal‑shock resistance, but it can pick up superficial scratches sooner than harder plastics. Polycarbonate offers excellent clarity and is often more scratch‑resistant in service, which is why it’s widely used in busy hospitality environments, though it is not BPA‑free and thus requires careful positioning. SAN sits in an interesting middle ground: it is highly scratch‑resistant and handles commercial dishwasher temperatures well, but it can crack if dropped on hard surfaces. For personalized tumblers, plastics can deliver clarity, color depth, and low weight, but they do not match stainless for long‑duration insulation, and some may show more visible scuffs if the finish is not protected.

Glass and Crystal for Premium Personalization

Glass and crystal stand out for taste neutrality and top‑tier aesthetics; Auspace highlights how crystal’s refractive sparkle commands a premium in fine dining and gifting. For scratch resilience, tempered glass improves impact and thermal‑shock resistance over ordinary soda‑lime glass, while chemically strengthened glass can offer unusual toughness for its thinness, as seen in Wirecutter’s testing notes. However, glass and crystal remain heavier and more fragile than stainless or high‑impact plastics, and are better suited to at‑home or office contexts than backcountry commutes. For personalization, both glass and crystal support engraving and color treatments, with crystal allowing more intricate results per Auspace, but they are not the core choice for leak‑managed, travel‑ready tumblers that must survive abrasive contact in vehicle consoles and bags.

Ceramic and Hybrid Linings

Ceramic delivers neutral taste and heat comfort but adds weight and chipping risk. In stainless shells, ceramic linings can reduce metallic notes while maintaining exterior durability. Food & Wine testing called out the Fellow Rocky double‑wall stainless with a ceramic lining for stable temperatures and a refined sip feel, although it is hand‑wash only. Ceramic is appealing for premium positioning and taste, but if your brand leads with outdoor durability and scratch resilience under frequent movement, ceramic surfaces demand extra care in both production and after‑sale guidance.

Insulation and Leak‑Resistance Benchmarks

Vacuum insulation remains the gold standard for temperature retention because the vacuum reduces heat transfer by conduction and convection. JollyChef’s 2025 roundup and testing protocol details offer a realistic reference: many mainstream vacuum tumblers keep cold about 10 to 16 hours and hot about 5 to 8 hours. Aft‑market tests cited there show a YETI Rambler keeping a cold beverage from 32°F to 54.3°F across 24 hours, and cooling a hot beverage from 197.2°F to 125.6°F in 8 hours. On individual product pages, AFLOAT specifies up to 6 hours hot and 12 hours cold on a 22 oz stainless model, while brand claims around large‑format tumblers like the Greens Steel Beast cite over 12 hours hot and 24 hours cold. A leakproof or spill‑resistant lid is the second pillar: The Spruce Eats highlights how lid design, gasket integrity, and open‑vs‑closed use materially change retention and cleanliness. Outside Online and Serious Eats reinforce that real‑world performance depends at least as much on lid engineering and user behavior as on the shell itself.

Reference Item or Claim Source | Capacity | Hot Retention | Cold Retention | Notes |

|---|---|---|---|---|

AFLOAT 22 oz stainless tumbler | 22 oz | Up to 6 hours | Up to 12 hours | Powder‑coated, leak‑resistant lid, drop‑resistant shell |

Typical vacuum tumbler per JollyChef testing | 16–20 oz common | About 5–8 hours | About 10–16 hours | Ranges vary by brand, lid closure, and environment |

Greens Steel Beast brand claim | 30 oz | Over 12 hours | Over 24 hours | Dishwasher‑safe; includes straws and splash‑proof lid |

YETI Rambler test results noted by JollyChef | Not specified in excerpt | From 197.2°F to 125.6°F over 8 hours | From 32°F to 54.3°F over 24 hours | Lid open time reduces hot duration significantly |

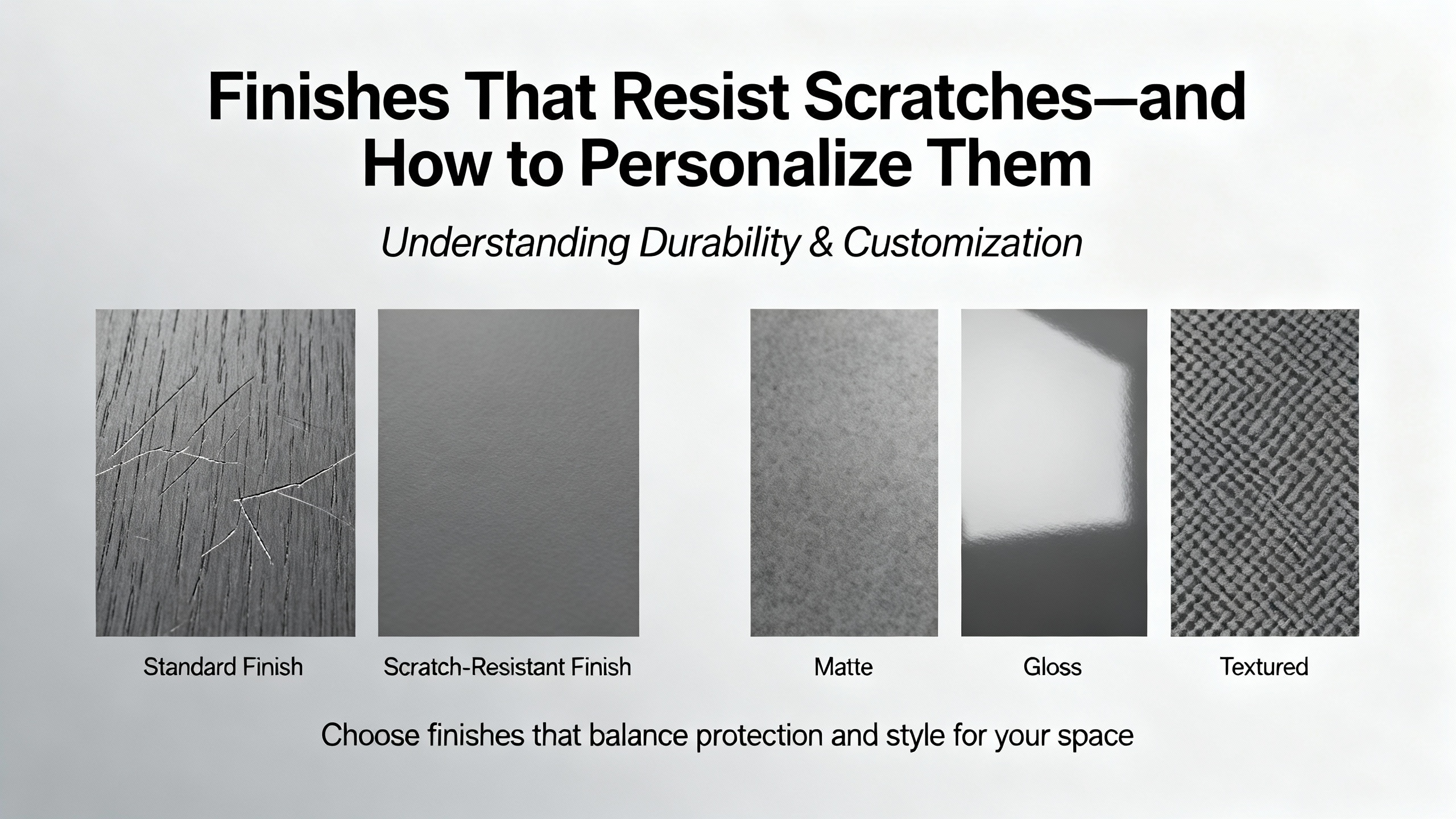

Finishes That Resist Scratches—and How to Personalize Them

A powder‑coated exterior is the most common route to a grippy, scratch‑resistant surface on stainless steel tumblers. The AFLOAT product page exemplifies why this matters: the tactile grip helps prevent drops, and the powder coat masks light scuffs better than bare steel or glossy plastics. For personalization, engrave‑through approaches remove a thin layer of coating to reveal stainless beneath, which creates a crisp, permanent mark while preserving the surrounding finish. Etching and laser engraving are readily supported in stainless workflows and are explicitly encouraged for stainless blanks by Ohway Flask. UV‑cured color printing on powder‑coated shells is attractive in full color when adhesion is correctly tuned but is only as durable as the ink stack and clearcoat used; heavy abrasion in cup holders can eventually show rub lines, so brands should align finish choice with the expected duty cycle.

Glass and crystal support both engraving and color layering, with Auspace noting crystal’s suitability for intricate designs at premium price points. Plastics vary: Tritan and polycarbonate can accept prints and texture effects, but Simply Smart Living’s testing notes that plastics in general are more prone to scratching than glass and some hard‑coat treatments, and SAN, while highly scratch‑resistant in washing, can crack on direct impacts. That means polymer‑based personalization needs realistic care instructions and thoughtful placement on the tumbler where abrasion is minimal.

Substrate | Common Personalization Methods | Durability Against Abrasion | Practical Notes |

|---|---|---|---|

18/8 stainless with powder coat | Laser engraving, UV color print, wrap graphics | Engrave‑through marks are highly durable; printed color durability depends on ink and clearcoat | Strongest all‑around choice for on‑the‑go pods; coating masks minor scuffs |

Tritan or polycarbonate | UV print, embedded patterns, molded textures | Surface scuffs show faster on Tritan; polycarbonate is typically more scratch‑resistant | BPA status differs by resin; verify dishwasher guidance per brand |

SAN | UV print, color textures | Very scratch‑resistant in dishwashing; can crack on hard drops | Good for high‑temperature washing environments |

Glass or crystal | Engraving, color treatments | Surface is hard, but drop fragility remains | Crystal enables intricate designs; tempered glass improves impact resistance |

Ceramic‑lined stainless | Engraving on exterior; interior lining unprinted | Exterior durability follows the shell finish; interior lining is for taste | Often hand‑wash only depending on brand guidance |

Real‑World Wear: What Independent Tests Tell Us

Independent and editorial testing offers a clear pattern. Food & Wine’s hands‑on reviews of unbreakable glasses found that double‑wall stainless steel, including models with ceramic linings, delivered stable temperatures and a balanced hand‑feel, though certain premium pieces were hand‑wash only. The Spruce Eats’ insulated picks highlight that lid design and dishwasher compatibility shape daily satisfaction as much as the shell itself. Wirecutter’s durability testing of drinking glasses underscores that tempered glass tends to crumble into relatively dull cubes when it fails, while chemically strengthened thin glass can be surprisingly resilient until it reaches its breaking point. Family Handyman’s evaluation of smart tumblers shows the trade‑offs that arrive with electronics and app‑tracking: bodies that are not fully dishwasher‑safe and lids that may not be leak‑proof, which matters for return rates. These findings reinforce a fundamental rule for POD tumblers marketed as scratch‑resistant and personalized: prioritize a rugged exterior, a leak‑tuned lid that users actually keep closed during transport, and cleaning guidance the buyer can easily follow.

Building a Scratch‑Resilient POD Tumbler Program

Product Spec Blueprint

Start with an 18/8 stainless vacuum tumbler in the 16 to 22 oz core range to maximize cup‑holder compatibility and daily carry weight. Add a powder‑coated exterior for grip and light scuff masking, and pair it with a leak‑resistant lid that uses a well‑seated gasket and a locking or slider mechanism suitable for one‑handed operation. The AFLOAT 22 oz example and Coopers Old Time Pit Bar‑B‑Que’s 20 oz stainless tumbler both emphasize rugged shells, travel lids, cup‑holder fit, and easy cleaning, which are the core signals buyers scan for in product images and copy. If you plan to sell larger 30 oz formats that stretch retention claims, align the messaging with data patterns described by JollyChef: cold can extend into the teens of hours with the lid closed, while hot typically lands in the mid‑single‑digit hours; if the lid is left open often, hot performance drops materially.

Personalization Workflow

Use laser engraving as your baseline for powder‑coated steel when “wear‑forever” marks are the promise. It creates sharp contrast, does not add a layer that can rub off, and scales for small batches without long drying times. Reserve full‑color UV printing for high‑impact graphics when the use case is lighter abrasion, and verify adhesion on the exact coating you source. For stainless blanks without coatings, etching produces an elegant, permanent mark with a minimalist look as noted by Ohway Flask. On glass or crystal, lean into engraving or tasteful color treatments for premium gifting, as Auspace suggests, and position these as at‑home or office ready rather than adventure gear.

Quality Control and Durability Testing

Adopt test protocols that mirror what buyers do in real life. JollyChef’s testing setup is a useful template for retention and leak performance: start hot beverages around common coffee temperatures and measure decline over several hours in a room‑temperature setting; test cold with ice‑water baselines; flip for brief intervals to check leaks; and run hip‑height drops to gauge denting and lid integrity. Food & Wine, Wirecutter, and The Spruce Eats all emphasize that how a product behaves after repeated dishwasher cycles and everyday handling is what determines lasting satisfaction. For scratch resilience, include a simple cup‑holder abrasion simulation and a repeated rub with a damp microfiber cloth across printed zones to check for visible ink transfer after drying. None of these tests require lab gear, but they do require discipline and a record of results you can act on.

Packaging and Dropshipping Readiness

Auspace’s wholesale guidance is blunt about transit: fragile or premium finishes need reinforced packaging, corner protection, and abrasion‑free cushioning that does not leave marks. Powder‑coated shells scuff if they move against hard inserts; lids can deform gaskets when over‑compressed; transparent bodies cloud when rubbed against unsealed corrugate dust. Use non‑abrasive wraps, immobilize the lid and body, and include a quick‑start care card on top so customers see it first on unboxing. For dropshipping, pilot shipments to yourself to document any rub points before you scale.

Compliance and Sustainability Signals

Safety and sustainability are purchase drivers, especially for corporate orders. Tritan is BPA‑free; polycarbonate is not; stainless 304/18‑8 is BPA‑free and naturally resistant to corrosion and odors, with Greens Steel noting electropolished interiors that resist harboring bacteria. The Amazon Climate Pledge Friendly pathway via the Global Recycled Standard calls for at least 50 percent certified recycled content to qualify, verified by auditors such as SGS; if your line includes recycled packaging or accessory components that meet GRS criteria, call it out succinctly. Ohway Flask cites a Statista datapoint that about seven in ten buyers prefer recycled materials, which makes recycled packaging and transparent material callouts worth the extra line in your product description.

Pros and Cons by Material for Personalized, Scratch‑Resistant Tumblers

Material | Scratch and Wear Behavior | Insulation and Leak Options | Personalization Fit | Taste and Safety | Typical Trade‑offs |

|---|---|---|---|---|---|

18/8 stainless | Very durable shell; powder coats resist light scuffs and improve grip | Best with double‑wall vacuum; supports robust leak‑resistant lids | Laser engraving is crisp and permanent; UV color requires adhesion control | Neutral when well‑finished; BPA‑free; corrosion‑resistant | Opaque base; weight can rise in large sizes |

Tritan | Strong impact and thermal‑shock resistance; can scratch with abrasion | Better for casual insulation; double‑wall options exist without vacuum | Clear body supports bold print; surface scuffs are more visible | BPA‑free; resists odors; clear visual appeal | Not as insulating as stainless; visible wear if scuffed |

Polycarbonate | High scratch resistance versus other plastics; excellent clarity | Moderate insulation in double‑wall designs | Takes prints and textures well | Not BPA‑free; position carefully for health‑sensitive buyers | Perception risk in some markets due to BPA association |

SAN | Very scratch‑resistant in dishwashing; heat tolerant | More about durability than long insulation | Prints well; holds color and texture | Foodservice‑ready durability | Can crack when dropped on hard surfaces |

Glass or crystal | Hard surface resists minor scuffs; tempered options improve durability | Minimal insulation unless double‑wall; more fragile than steel | Engraving and color treatments elevate premium gifts | Pure flavor; high visual appeal | Heavier; drop fragility; indoor‑oriented |

Ceramic‑lined stainless | Exterior follows the shell; interior lining for taste | Vacuum steel exterior; interior aids flavor neutrality | Exterior marking only; interior remains pristine | Excellent taste; premium feel | Often hand‑wash only; higher cost |

Pricing, Positioning, and Catalog Strategy

Market demand rewards brands that balance durability, aesthetics, and personalization latitude. Auspace notes a clear trend toward colored drinkware for brand alignment, which dovetails with powder‑coated stainless shells that accept engraving or UV color and mask minor scuffs. If your audience favors outdoor resilience, lead with vacuum stainless models carrying honest retention statements aligned to JollyChef’s test ranges, and show the travel lid locked in your hero image. If your line targets home entertaining and visual elegance, borrow from Food & Wine and The Spruce Eats playbooks with tasteful glass, SAN, or Tritan entries that stack well, feel good in hand, and are explicitly dishwasher‑friendly where appropriate. Corporate and event buyers respond to low minimums, so Ohway Flask’s low‑MOQ signal matters; back it up with a clean ordering flow for engraving files and preflight checks. For B2B kits, consider bundling lids with straws or magnet sliders where brands like Greens Steel and The Spruce Eats found value, and make spare gaskets easy to add at checkout to reduce service tickets later.

Care and After‑Sale Guidance That Reduces Returns

Clear care instructions keep scratch‑resistant products looking new. The Spruce Eats and DHgate’s buying guides align on simple, effective maintenance: stick to warm soapy water and wide‑mouth designs for easy access, confirm whether bodies and lids are truly dishwasher‑safe, and remind buyers to store tumblers with lids off to prevent odors. For polymer bodies, Simply Smart Living recommends top‑rack dishwasher positions when allowed and cautions against abrasives that haze surfaces; hand‑washing acrylic extends its clarity. Food & Wine’s tests of premium stainless and ceramic‑lined pieces often call for hand‑washing, which is worth stating explicitly. Every care card should close with a one‑line definition of leak‑resistant behavior to set expectations: seals reduce spills when closed, but upside‑down transport is not recommended unless the lid is explicitly rated leakproof.

Sourcing and Supplier Management

Before you scale, validate three things with your supplier. First, run small‑batch personalization in your facility or with your fulfillment partner on the exact coating and resin they will ship; adhesion and edge quality vary by batch. Second, conduct a short retention and leak test like the JollyChef protocol to catch lid or gasket drift. Third, ship a pilot box to yourself and a colleague in another state to assess packaging rub, as Auspace warns about transit handling. If you serve corporate buyers or retailers, add a certificate library that captures BPA statements for polymers and materials disclosures for stainless, and note any recycled‑content certifications like GRS where your packaging or accessory mix qualifies under the 50 percent threshold used for Climate Pledge Friendly designation on large marketplaces. These steps convert “scratch‑proof” aspiration into a repeatable, resilient customer experience.

A Short FAQ on Scratch Resistance and Personalization

Are truly scratch‑proof tumblers possible?

The most accurate claim is scratch‑resistant. Durable shells such as 18/8 stainless with powder coats tolerate daily abrasion better than clear plastics, and SAN resists scratches in washing exceptionally well, but no finish is impervious to sharp metal contact or long grinding in a tight car console. Setting correct expectations reduces returns and aligns with how sources like Rowdy Crowd and Sur La Table frame durability.

Which personalization method lasts longest on stainless?

Laser engraving into a powder‑coated shell is the most durable option because it removes a thin surface layer and reveals the steel beneath. It does not add a printed film that could rub away. UV‑printed color is attractive for complex art, but its durability depends on ink chemistry, cure, and clearcoat quality. Guidance from Ohway Flask and Auspace supports choosing engraving for long‑life branding and using color prints where abrasion is lighter.

What should I promise customers about temperature retention?

Use realistic language anchored in third‑party testing. Round out your copy with data patterns from JollyChef and editorial reviewers: many vacuum tumblers keep beverages hot for about several hours and cold beyond half a day, with larger sizes and closed lids extending cold performance meaningfully. If you cite a brand claim, mark it as such and keep expectations in line with the scenario your buyers will actually use.

Closing

Scratch‑resistant personalization is not a single feature; it is a system. When you pair an 18/8 vacuum shell, a powder‑coated exterior, engraving‑first artwork, leak‑tuned lids, and thoughtful packaging—and you echo care guidance proven by editorial testing—you ship a tumbler program that earns repeat orders. Build that system once, and your brand can scale designs, seasons, and sales channels with confidence.

References

- https://www.surlatable.com/o?c=scratch-resistant-drinking-glasses&srsltid=AfmBOopqHNnaIhH_nDYt12Q44fQV7mLvuchEORVIC0gvcRpUYbdiXs17

- https://www.tervis.com/outdoors?srsltid=AfmBOop7bQVTul8MtDYcEjTud9wY2hkMuyigCYWt88s2glSta93X6o5r

- https://www.thespruceeats.com/best-plastic-drinking-glasses-5104803

- https://afloatpro.com/products/22-oz-bison-tumbler-mint?srsltid=AfmBOoqOoV8NGV6h90HIc3O2oZ0C3kunAd_-02UWLEOlBIX-FRjv8sdX

- https://www.amazon.com/Insulated-Tumblers-Scratch-Resistant-Beverage-Containers/s?rh=n%3A21613423011%2Cp_n_feature_nine_browse-bin%3A23539998011

- https://auspacekitchenware.com/best-materials-for-durable-drinkware-sets-in-wholesale-market/

- https://www.coolnicetumbler.com/4-tumblers-for-camping-what-to-look-for/

- https://www.designdekko.com/blog/the-ultimate-drinkware-and-tumbler-buying-guide-select-the-right-one-as-per-lifestyle-and-needs

- https://smart.dhgate.com/how-to-choose-a-durable-travel-coffee-tumbler-perfect-for-outdoor-adventures/

- https://us.fable.com/products/glassware-set