Quality Stitching in Custom Products: Expert Craftsmanship for On‑Demand Brands

As someone who has walked dozens of founders through the messy middle of scaling print‑on‑demand and dropshipping brands, I can tell you this: the print gets you the sale; the stitching decides whether you keep the customer. You can have a stunning design, a slick storefront, and fast shipping. If the seams twist, split, or pucker after a few wears, your repeat orders and referrals evaporate.

This article breaks down what “quality stitching” really means in technical terms, how researchers and industry practitioners evaluate seam performance, and how you can turn that knowledge into simple, practical checks for your own custom products and suppliers.

Why Stitching Quality Is the Silent Deal‑Breaker

A 2020 review chapter by Madhuri Kakde positions seam quality alongside fabric quality as one of the primary determinants of garment durability and visual performance. That conclusion mirrors what we see every day in e‑commerce operations: when seams fail or look sloppy, customers perceive the entire product as cheap, no matter how premium the print or fabric.

Stitching quality quietly shapes three pillars of your brand:

First, it drives durability. Poorly designed or executed seams reduce seam strength and seam‑slippage strength. Garments then fail at the stitch line rather than in the body fabric, leading to popped underarms, open pockets, and side seams that separate under everyday stress.

Second, it shapes appearance. Seam puckering, crooked stitching, and mismatched seam lines make even a great fabric look wrinkled, twisted, or “off.” Several technical reviews highlight seam puckering as a common consequence of heavier fabrics combined with heavier threads and suboptimal process choices.

Third, it affects comfort and function. Rough internal seams, bulky joins, and poorly finished edges rub against the skin, irritate high‑movement areas, and make pockets, waistbands, or zippers feel fragile or annoying to use. A uniform‑focused article from Gubbacci emphasizes that internal stitching quality is critical to appearance, durability, comfort, and functional features such as panels and pockets.

For an on‑demand or dropshipping business, all three dimensions show up directly in reviews, returns, and word‑of‑mouth. You might never hear the words “seam efficiency” from a customer, but you will hear “fell apart after a week.”

What “Seam Quality” Really Means

Technical literature on sewing treats seam quality as a combination of mechanical performance and visual and comfort characteristics over the entire service life of the garment. When researchers talk about a high‑quality seam, they are usually asking two questions.

The first question is whether the seam can reliably carry the loads a garment experiences without failing. This covers seam strength under tension, resistance to seam slippage, and how well the seam retains its properties after laundering and wear.

The second question is whether the seam maintains a smooth, attractive appearance and feels comfortable to the wearer. This brings in seam puckering, distortion, and sewing damage to the fabric near the stitch line, as well as how the seam feels next to the skin.

A comprehensive review accessible via ResearchGate defines several core failure modes that undermine seam quality. These include seam slippage, where the fabric pulls away along the stitch line; inadequate seam strength, where the seam breaks before the surrounding fabric; seam pucker, where ridges and wrinkles appear along the seam even when the garment is new; and sewing damage, where the needle and thread physically harm the fabric structure.

Researchers also introduce the concept of seam efficiency, typically expressed as the ratio of seam strength to the strength of the unsewn fabric. Kakde’s review notes that seam efficiencies around roughly sixty to eighty‑plus percent are common and that pushing far beyond that range is difficult in practice. For a brand owner, this matters because it highlights the trade‑off between seam strength, fabric behavior, and economics. Chasing “indestructible” seams can easily backfire with stiffer garments, more puckering, higher needle damage, and longer production times.

It helps to translate these technical ideas into business language. The table below connects common seam metrics to what you actually experience in your store.

Technical Metric | What It Captures | What You See in Your Business |

|---|---|---|

Seam strength | Load a seam can carry before breaking | Popped underarms, open side seams, broken waistband stitching |

Seam‑slippage strength | Resistance of fabric to pulling away along seam line | Seams that stay intact but show gaping or distortion |

Seam efficiency | Seam strength relative to the base fabric strength | Garments failing at the seam instead of the fabric |

Seam puckering | Ridges or wrinkling along seams | New garments that look wrinkled or “cheap” right out of the bag |

Sewing damage | Needle or thread harm to fabric (yarn breakage, holes, runs) | Tiny holes along seams, runs in knits, early tearing after washing |

Understanding these constructs makes you far more effective when you talk with suppliers, evaluate samples, or troubleshoot customer complaints.

The Fabric–Thread–Stitch System Behind Every Seam

Seam quality is not an isolated property of the stitching alone. It is the result of how fabric characteristics, thread properties, stitch and seam constructions, and machine settings interact. Kakde’s review and the broader seam‑quality literature emphasize that these factors must be selected and tuned together rather than in isolation.

Fabric Characteristics

Fabric structure and mechanical behavior set the foundation for seam performance. Wovens, knits, elastic fabrics, denim, chenille, satin, leather, and technical performance fabrics all respond differently under load and during stitching.

The comprehensive seam‑quality review summarized in the ResearchGate source highlights that fabric structure, yarn type, elasticity, and surface properties all drive seam slippage, seam efficiency, and damage risk. For example, elastic wovens and satins are especially prone to seam slippage and puckering if the seam construction and process parameters are not carefully matched to the fabric.

For a print‑on‑demand seller, this means that you cannot assume the same stitching approach should be applied to both a heavy hoodie and a lightweight performance T‑shirt. The underlying fabric dictates which stitch types, seam constructions, and process settings are appropriate.

Thread, Stitch Class, and Seam Type

The Gubbacci uniform article underlines the importance of thread quality and stitch type. Threads must match the fabric both in strength and in visual tone. Sturdy yet fine threads that blend with the fabric give a polished look, whereas coarse or mismatched threads make garments appear lower quality even when they are functionally adequate.

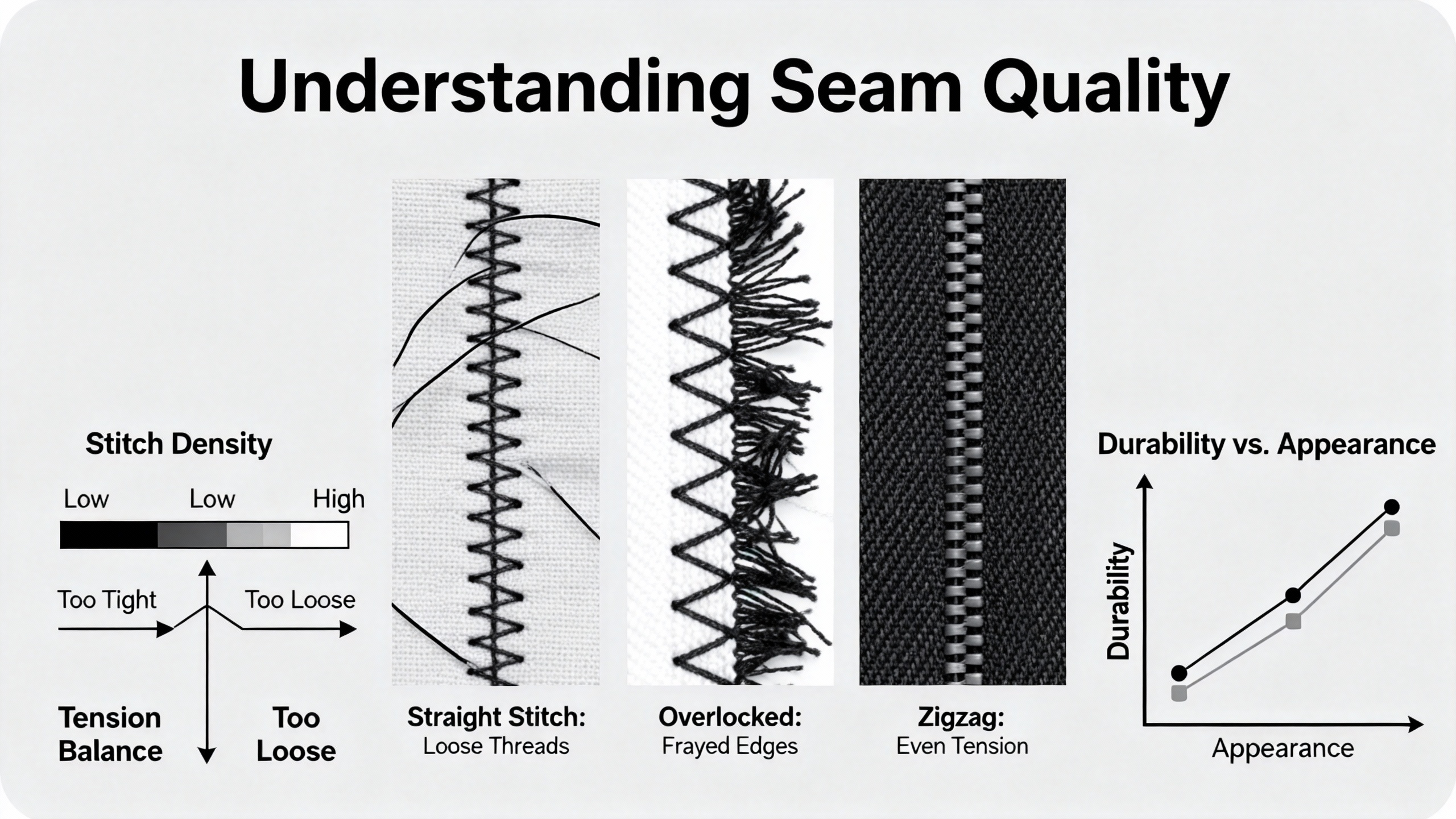

Stitch type and stitch length are equally important. Gubbacci notes that appropriate stitch choices, such as chain stitch for flexibility and lockstitch for durability, combined with even spacing of roughly ten to twelve stitches per inch, are strong indicators of good construction. Chain stitches can flex with movement, making them suitable for areas where stretch is important. Lockstitches provide robust, secure seams where stability matters more than stretch.

The academic reviews caution that manufacturers often neglect the correlation between stitch classes, seam types, and overall seam performance. Selecting a visually familiar seam style without considering fabric behavior and use case leads to garment failures even when the fabric itself is high quality. For instance, using a rigid seam construction on a stretch fabric can increase sewing damage and slippage, while using a stretchy seam on a high‑load structural area can reduce seam strength below acceptable levels.

Machine and Process Parameters

Even with the right fabric, thread, and seam architecture, poor machine setup can ruin seam quality. The ResearchGate‑summarized review of seam parameters cites sewing speed, needle size and point geometry, thread tension, stitch density, presser‑foot pressure, and needle temperature as important process variables.

Higher sewing speeds, combined with friction, can raise needle temperature and increase the risk of sewing damage in sensitive fabrics. Inadequate or excessive thread tension and presser‑foot pressure can worsen seam puckering and distort the fabric along the stitch line. Stitch density that is too low compromises strength and slippage resistance, while very high density can stiffen seams, increase puckering, and damage the fabric.

From a brand owner’s perspective, you do not need to tune these variables yourself, but you should expect your suppliers to understand and control them. When a supplier treats sewing as an afterthought and rarely adjusts machines for fabric changes, seam issues become inevitable.

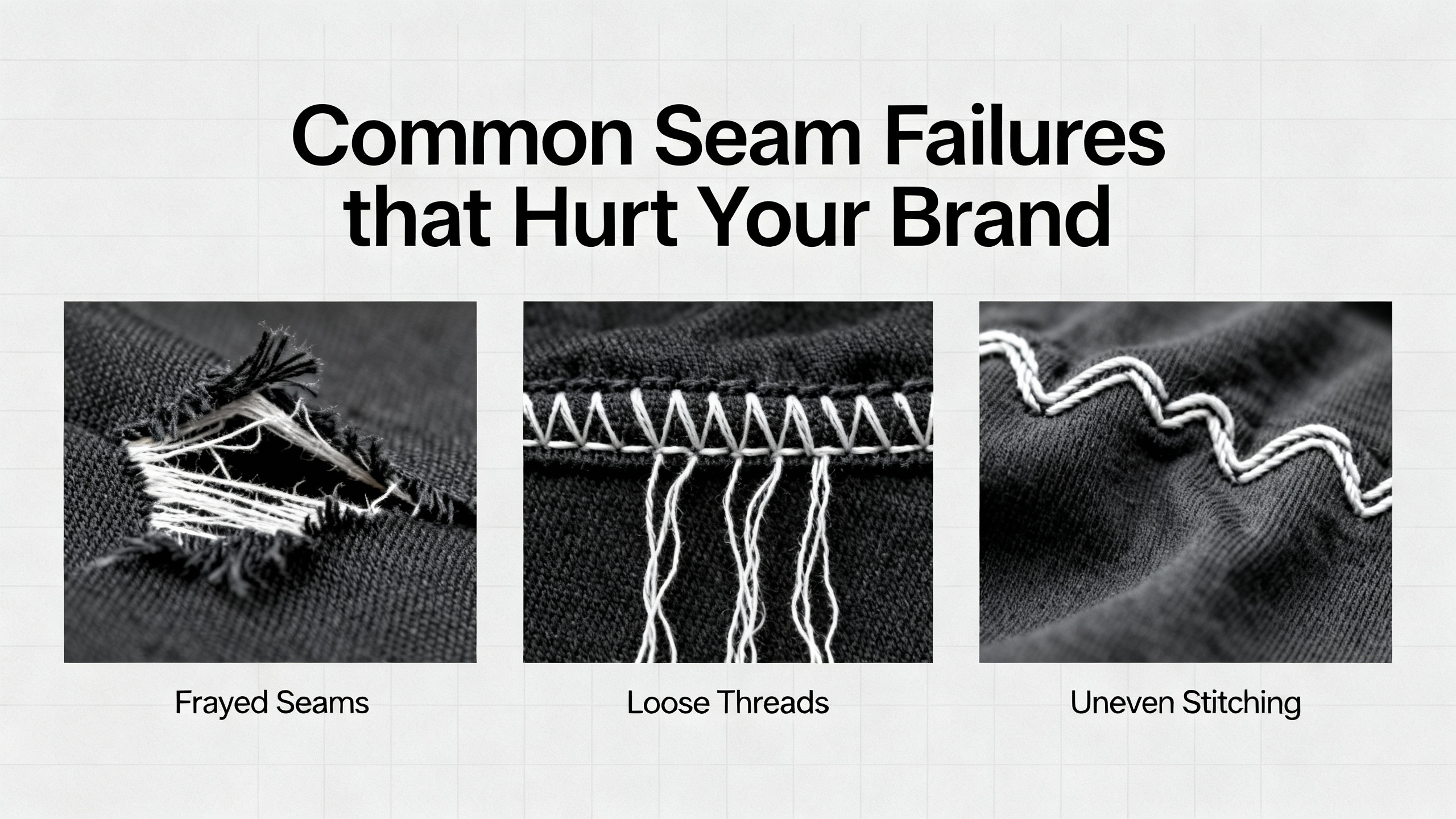

Common Seam Failures that Hurt Your Brand

Recognizing failure modes in real garments helps you connect technical concepts to customer complaints.

Seam strength failures show up as outright breaks in high‑stress zones: shoulders, underarms, crotch seams, and pocket attachments. The Gubbacci article explicitly recommends checking for reinforcements and backstitching at seam start and end points in stress areas such as shoulders, underarms, and pockets. When these reinforcements are missing or poorly executed, seams can open under normal wear, leading to embarrassing failures for your customers and returns for you.

Seam slippage failures are more subtle. Instead of the stitches breaking, the fabric yarns near the seam shift. You see gaping at the seam, distorted plaid or stripe matching, or shapes that look twisted even when the garment is laid flat. The ResearchGate‑based review notes that seam slippage is a major issue in fabrics such as chenille, satin, and elastic wovens, and that specialized techniques are often needed to reduce it.

Seam puckering undermines appearance even when seams are mechanically sound. Kakde’s review points out that seam puckering tends to increase with heavier fabric weights and higher sewing‑thread linear density. The result is a garment that appears wrinkled and cheap along seam lines, even when fresh out of the package. In the context of printed apparel, seam puckering can distort printed graphics near seams and make customers feel that the product deviates from the glossy mockups they saw on your site.

Sewing damage appears as small holes, runs, or weakened fabric along the stitch line. The comprehensive review references work on sewing damage in knitted fabrics and other materials, showing that needle type, needle size, and process conditions all influence this risk. Damage may not be obvious at first inspection but can lead to early tearing or runs after a few washes.

Finally, comfort defects often come from internal seam finishing and bulk rather than outright structural failure. Gubbacci stresses that internal seam finishing should use overlocking or similarly neat methods that leave edges smooth and free of loose threads, and that such finishes must allow flexibility in stretch fabrics without causing irritation. Bulky joins, scratchy overlock threads, and poorly trimmed thread tails can make uniforms, tees, or joggers feel unpleasant against the skin, especially at necklines, waistbands, and inner thighs.

Quality Control in Sewing: A Habit, Not a Final Check

Practical voices from the sewing community reinforce what the research suggests. A short but pointed post from the Tailors Zone community describes quality control in sewing as checking your work at every stage to ensure high standards in fit, finish, durability, and appearance. Learning to do this systematically is framed as a powerful step toward producing professional, durable, and beautiful garments.

This mindset is directly relevant to how you manage suppliers and internal teams. Quality stitching is not something you inspect only on the final product. It is the result of consistent checks at each stage: cutting, initial seams, assembly of panels, attachment of pockets and trims, and final finishing.

For a print‑on‑demand brand, you may not own the machines, but you can borrow the habit. Require your suppliers to show how they inspect seam quality during production, not just at the shipping stage. Ask how they monitor metrics like seam strength, seam‑slippage strength, and seam appearance. According to Kakde’s review, systematic evaluation of such metrics is central to robust seam‑quality management programs.

How to Evaluate Stitching Quality in Supplier Samples

You do not need a lab to spot many stitching issues. A structured, hands‑on inspection process for samples will dramatically reduce your risk before you commit to a supplier or a new product line.

Start with visible stitch quality. Examine external seams for straightness, consistent spacing, and symmetry. The Gubbacci guidance emphasizes that straight lines and mirror‑image seams on both sides of the garment are important for both structural integrity and appearance. Run your finger along the seam and notice whether stitch spacing feels consistent. If you see wandering lines, varying spacing, or inconsistent seam allowances, treat this as a red flag about process discipline.

Next, look for loose threads and finishing quality. Loose or hanging threads at seam ends, buttonholes, or pocket edges suggest that backstitching or bar‑tacking is weak or missing and that thread trimming is careless. Over time, those loose ends can unravel under washing and wear.

Then, inspect internal seams and finishing. Turn garments inside out. Gubbacci advises that internal seam finishing should use overlocked or otherwise neatly finished edges that are smooth to the touch, with no loose threads and no sharp or scratchy ridges. Pay special attention to necklines, waistbands, armholes, underarms, and the inside of pockets. These are places where the wearer will constantly feel the seam.

Check high‑stress points deliberately. At shoulders, underarms, side seams near the hip, and around pockets and belt loops, gently apply tension along the seam line. You are not trying to break the garment, but you want to see whether the seam holds its shape without obvious distortion or sound of threads snapping. Reinforcements and backstitching should prevent the seam from “unzipping” under this kind of handling.

Finally, evaluate overall fit and silhouette, especially for more tailored products. A detailed checklist shared in a tailoring answer on Quora illustrates how professionals evaluate suit quality. It emphasizes shoulder alignment, sleeve length, jacket length, waist shaping, trouser length, and taper. For example, jacket shoulders should align with your natural shoulders without divots, sleeves should allow a modest amount of shirt cuff to show, and the jacket waist should close cleanly without an “X” of pulling wrinkles, leaving roughly a couple of inches of breathing room when you gently pull it forward. Traditional trouser lengths place a slight break on the shoe, while more contemporary styles hem trousers slightly above the shoe.

Even if your brand focuses more on tees and hoodies than on tailored suits, the underlying lesson applies. Fit is part of perceived quality, and poor stitching often reveals itself as distortion in the garment silhouette: twisted side seams, hems that roll or flare unevenly, and collars that do not lie flat.

Turning Seam Science into Supplier Strategy

Technical research on seam quality might seem far removed from daily e‑commerce decisions, but it offers clear guidance on how to build and negotiate with your supplier ecosystem.

First, select suppliers who treat seam quality as part of engineering, not just aesthetics. The ResearchGate‑summarized review emphasizes integrated optimization: fabric design, seam construction (including stitch type and density and thread selection), and sewing‑machine parameters must be tuned together. When you vet suppliers, ask how they choose stitch classes and seam types for different fabrics and end uses. Do they adjust stitch density and tension for heavy versus light fabrics? How do they handle challenging materials such as elastic performance knits or slippery satins?

Second, look for evidence of systematic testing. Kakde’s review stresses the importance of monitoring seam strength, seam‑slippage strength, seam efficiency, puckering, and damage as part of process control. Ask suppliers what tests they use and what minimum standards they target for high‑stress garments such as uniforms, workwear, and sportswear. Even if you do not need the full technical details, their ability to discuss these topics with confidence is a strong signal.

Third, recognize that seam quality is not free. Increasing stitch density, using higher‑quality thread, adding reinforcements, and slowing machines to reduce needle damage all cost time and materials. You will need to segment your product portfolio. For premium, brand‑defining products, you may accept higher production costs in exchange for superior stitching standards. For low‑margin promotional items, you might accept simpler seam constructions while still insisting on basic thresholds for strength and appearance.

However, the research on seam efficiency reminds us that more is not always better. Pushing seam strength far beyond typical efficiency ranges can introduce new issues like stiffness and puckering. The goal is balanced optimization, not maximizing any single metric.

Technology’s Role: Objective Seam Evaluation and AI

One of the more forward‑looking themes in the seam‑quality literature is the move from subjective to objective evaluation, often supported by advanced analytics.

The comprehensive review accessible via ResearchGate describes objective methods and artificial intelligence‑based approaches for evaluating seam puckering and predicting seam appearance quality. The aim is to reduce reliance on human graders, whose assessments can vary, and instead use standardized measurements and image‑based analysis to score seam appearance. Other research cited in that review explores machine‑learning techniques for selecting suitable sewing needles and tuning process parameters to match specific fabrics and garments.

For small and mid‑sized e‑commerce brands, you may not implement these technologies directly. However, awareness of them can inform supplier selection. If a large fulfillment partner mentions that it uses objective seam‑quality evaluation or AI‑assisted parameter selection, it signals a more mature quality culture. Even smaller factories can adopt parts of this mindset by standardizing tests and recording seam‑strength and slippage results over time.

As automation and data‑driven decision‑making continue to spread in apparel manufacturing, expect seam quality to become more quantifiable. This will ultimately benefit on‑demand brands that demand transparency and consistency from their partners.

Building a Quality‑First Culture in Your Custom Product Brand

At the founder level, stitching can feel like a technical detail that belongs on the factory floor. In reality, it is a strategic lever. It drives brand trust, customer lifetime value, and the viability of premium positioning.

Adopt the same philosophy that experienced tailors and uniform specialists use. Treat quality control as a continuous habit, not a final inspection. Learn to read seams as carefully as you study print proofs. Evaluate samples with a disciplined eye for strength, slippage, puckering, finishing, and fit. Ask suppliers about their seam‑quality practices and listen for answers grounded in coordinated choices of fabric, thread, stitch, and process.

When you pair strong visual branding and compelling designs with reliable, comfortable, and well‑engineered stitching, you convert first‑time buyers into long‑term fans. In the crowded world of on‑demand printing and dropshipping, that quiet craftsmanship is often the most durable competitive advantage you can build.

FAQ

Is stitching quality really that important if my prints look great? Yes. Research reviews consistently place seam quality alongside fabric quality as a primary driver of garment performance and customer perception. Community advice from sewing professionals also frames quality control in stitching as a key step in moving from hobby‑level to professional results. Customers may buy for the print, but if seams fail or look sloppy, they quickly label the entire product as low quality.

How many stitches per inch should I look for as a basic quality indicator? Guidance from uniform specialists like Gubbacci highlights even spacing of roughly ten to twelve stitches per inch, combined with appropriate stitch types, as a strong sign of good construction. That range generally balances strength, flexibility, and appearance for many everyday garments, though specific fabrics and use cases may require adjustments.

What should I prioritize first when improving stitching quality with my supplier? Start by focusing on high‑stress areas and internal finishing. Ask your supplier to ensure strong, reinforced seams at shoulders, underarms, pockets, and waistbands, along with neat, smooth internal edges free of loose threads. Then, push for consistent stitch spacing and alignment along visible seams. These steps deliver noticeable gains in durability, comfort, and perceived quality without requiring you to overhaul your entire supply chain at once.

References

- https://www.academia.edu/79061491/Review_on_Analysis_of_Seam_Quality

- https://commons.emich.edu/cgi/viewcontent.cgi?article=1052&context=honors

- https://verso.uidaho.edu/view/pdfCoverPage?instCode=01ALLIANCE_UID&filePid=13325577750001851&download=true

- https://digitalcommons.unl.edu/cgi/viewcontent.cgi?referer=&httpsredir=1&article=2388&context=extensionhist

- https://epubl.ktu.edu/object/elaba:124950521/MAIN

- https://texas4-h.tamu.edu/wp-content/uploads/fashion_resource_clothing_quality_standards.pdf

- https://journals.uc.edu/index.php/JALCA/article/download/3387/2638/3858

- https://www.researchgate.net/publication/355075531_The_parameters_affecting_seam_quality_a_comprehensive_review

- https://www.realthread.com/blog/10-tips-to-determine-high-quality-garments

- https://shanghaigarment.com/what-are-the-key-factors-in-selecting-the-right-stitch-types/