Professional Grade Personalized Products: Commercial Quality Standards

Why “Professional Grade” Now Defines the Personalized Product Game

In on-demand printing and dropshipping, personalization used to be a novelty. Today it is a core expectation. Research compiled by Dataforest shows that around 78% of customers are more likely to make repeat purchases from brands that personalize, and more than four out of five say being recognized as individuals is critical to winning their business. At the same time, customers increasingly expect professional-grade quality, not “cheap custom merch.”

This is where many founders hit a wall. They master ads and creative, plug into a print-on-demand platform, then discover that inconsistent print quality, fading colors, damaged shipments, and safety complaints quietly drain profit and reputation. The commercial reality is simple: if your personalized products do not meet recognized quality standards, performance marketing will only accelerate your refunds.

Manufacturing and quality experts in sectors far more regulated than ours have already solved versions of this problem. From the quality management principles described by SafetyCulture and LP Centre, to the data-driven monitoring advocated by DELMIAWorks and MachineMetrics, to the rigorous product evaluation standards maintained by ASTM and overseen by regulators like the US Consumer Product Safety Commission (CPSC), there is a deep body of practice you can borrow.

As someone who mentors ecommerce founders, I see the same pattern repeatedly: brands that treat personalization and professional-grade quality as one integrated system build durable businesses. Those that treat quality as an afterthought get trapped in discounting, reputation damage, and platform risk. The rest of this article is about moving your personalized product line into that professional-grade category using commercially recognized quality standards.

From Novelty Merch to Professional Grade

When I talk about “professional grade” in personalized products, I do not mean perfection or luxury. I mean products that consistently behave like what established consumer brands would confidently put on shelves: predictable, safe, compliant, and built to last under normal use.

Professional-grade personalized products share four characteristics.

First, they deliver consistent performance. Customers who reorder a personalized hoodie six months later should receive the same fabric feel, fit, and print density as the first one. Manufacturers and quality specialists call this reducing process variation. Guide Technologies and LP Centre emphasize that clearly defined standards and repeatable processes are the foundation for consistent quality.

Second, they are durable in real-world conditions. A mug that looks perfect on arrival but chips or fades after a couple of weeks of dishwasher cycles is not commercial grade. Quality control resources like those from LP Centre and Ease highlight scrap rates, defect metrics, and field performance as essential indicators that go beyond initial inspection.

Third, they are safe and compliant for their intended use. SafetyCulture points out that formal quality standards and frameworks like ISO 9001 and Good Manufacturing Practices exist to ensure products are free from defects and process variation that could harm customers. ASTM’s consumer product evaluation standards add category-specific test methods and safety specifications for items that range from kitchen equipment to children’s products. For categories such as baby products or items used around water or heat, these standards are not optional.

Fourth, they generate reliable customer satisfaction and repeat purchase behavior. Dataforest and SuperOffice both show that personalization combined with a sense of being understood significantly boosts retention. But when personalization is layered on top of unreliable quality, disappointment multiplies. The same digital footprint that powers your marketing also amplifies quality failures through reviews and social media.

The shift you need to make as an ecommerce founder is to move your mental model from “selling a design” to “owning a product system” that includes manufacturing, standards, and continuous improvement.

Quality Assurance vs Quality Control in a POD Workflow

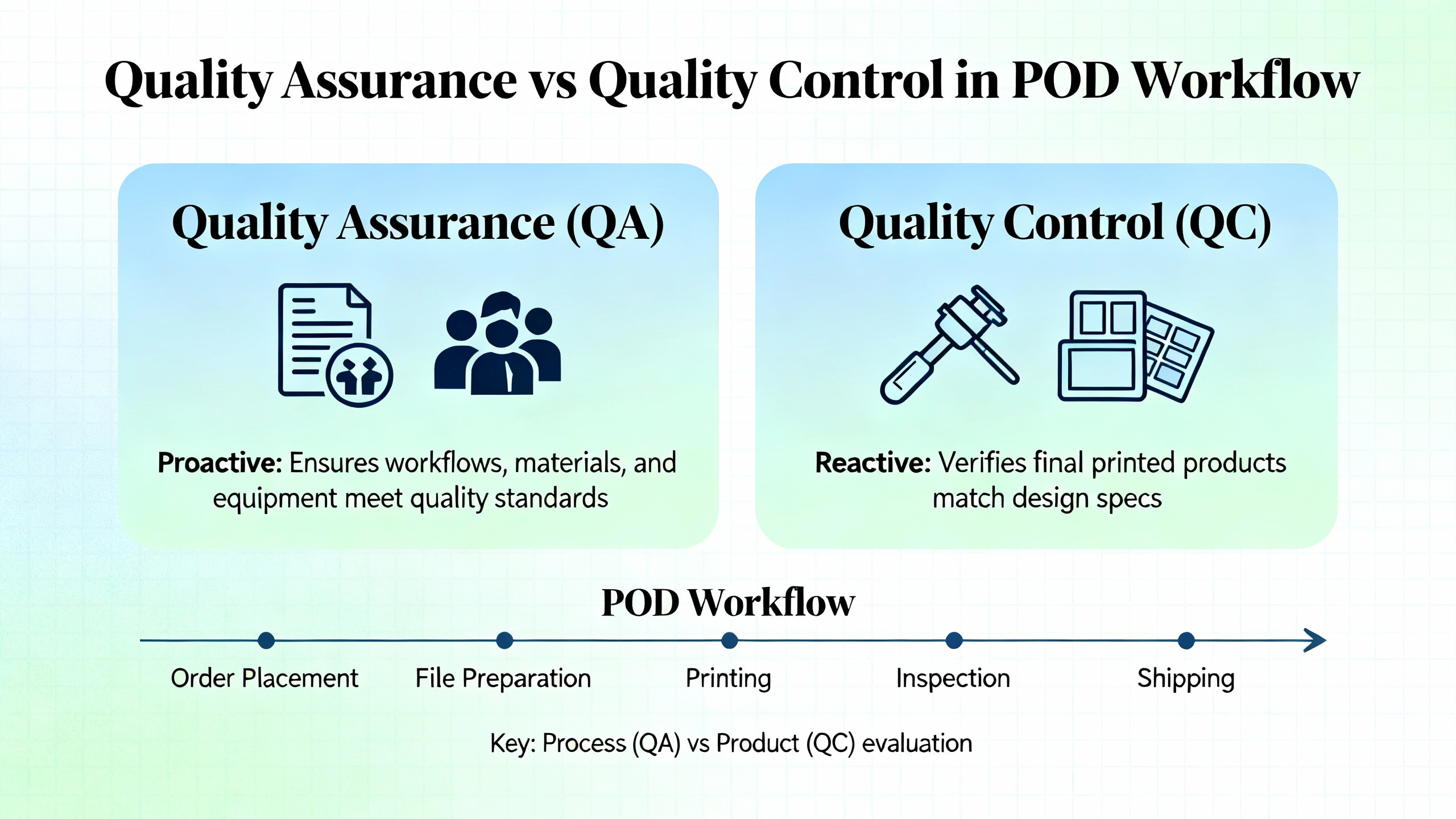

Most on-demand sellers use the words “quality checks” loosely. Manufacturing leaders draw a sharp distinction between Quality Assurance (QA) and Quality Control (QC), and appreciating that difference is essential when you rely on third-party printers and dropshippers.

Quality Assurance is the proactive side. As Endural and Guide Technologies describe, QA focuses on designing processes and systems that prevent defects before they occur. In your world, QA looks like standardizing print-ready file formats, locking color profiles, defining approved blank products and inks, confirming that your suppliers’ processes align with relevant standards, and training your team on how to prepare orders correctly.

Quality Control is the reactive side. QC is about detecting and correcting defects in outputs through inspections, testing, and sampling. LP Centre and MachineMetrics both emphasize that QC operates at various points along production, from incoming material checks to final inspection before shipment. For on-demand printing, QC includes pre-production samples, in-line checks on print alignment and color, and pre-shipment inspections on a sample of finished units.

High-performing manufacturers treat QA and QC as complementary. DELMIAWorks describes quality management as a loop: real-time production monitoring feeds statistical tools that detect out-of-spec behavior early, while QA frameworks like Advanced Product Quality Planning (APQP) ensure that future runs learn from those signals. In your context, that might mean consistently logging which design types or fulfillment centers generate more reprints, then tightening your listing rules or supplier pool accordingly.

If you manage your brand but outsource production, your goal is not to become a factory. Your goal is to insist that your partners can demonstrate both QA and QC practices that align with your standards, and to integrate your data with theirs as tightly as your leverage allows.

Data-Driven Quality: Bringing Manufacturing Discipline to Personalization

Manufacturing leaders increasingly rely on real-time data and statistical tools to maintain quality. DELMIAWorks and Ease highlight the role of Overall Equipment Effectiveness (OEE), Statistical Process Control (SPC), and root cause analysis as levers to keep products within spec and reduce waste.

While you may not have direct control over shop-floor dashboards, you can adopt the underlying disciplines.

Start with clear, measurable quality metrics that matter for on-demand personalized products. Ease suggests grouping metrics into process, product, maintenance, and supplier categories. For a POD brand, this might translate into:

Print and production metrics such as first-pass yield for print jobs, average reprint rate per fulfillment center, and average time from order to print completion.

Customer-facing metrics such as customer complaint rate per 1,000 orders, return rate for quality reasons versus preference reasons, and average resolution time for quality tickets.

Supplier and logistics metrics such as incoming defect rate on blanks, on-time shipment percentage, and damage rate during transport.

Cost metrics such as your cost of quality, which Ease describes as the combination of the cost of poor quality (returns, refunds, reprints, and lost reputation) and the cost of good quality (preventive activities like testing and audits). Understanding this cost trade-off justifies investment in prevention.

Next, use data to identify patterns instead of chasing isolated incidents. Factored Quality’s work with brands shows that centralizing defect reporting into a single source of truth makes it possible to spot recurring issues, such as a specific print method failing on dark garments or a particular warehouse generating more damage in transit.

Continuous learning is not just a buzzword from AI recommendation literature. Dataforest notes that effective personalization systems update models as shopper behavior changes. Quality systems should do the same: as you gather more feedback and production data, adjust your standards, supplier mix, and product catalog.

Standards and Frameworks That Actually Apply to Personalized Goods

One hesitation founders often express is that quality standards sound like big-industry bureaucracy. In reality, they provide a shared language and set of expectations between you, your suppliers, and regulators.

Quality frameworks described by SafetyCulture, such as the seven quality management principles behind ISO 9000, translate directly into ecommerce operations. Customer focus, leadership, engagement of people, a process approach, improvement, evidence-based decision-making, and relationship management are all as relevant to a three-person Shopify brand as to a pharmaceutical plant. The difference is scale, not relevance.

Product-specific standards matter when you operate in sensitive categories. ASTM maintains detailed consumer product evaluation standards that cover safety and performance for many household and commercial goods, including children’s products, furniture, pools, and kitchen equipment. If your personalized line touches any of these areas, your supplier should be able to tell you which ASTM standards they design and test against.

Regulators like the CPSC, whose information quality guidelines outline how they evaluate and disseminate safety information, set the broader context. If you sell children’s items in the United States, you are operating in their world whether you realize it or not. The CPSC expects manufacturers and importers to adhere to standards and to ensure information is accurate, unbiased, and backed by reproducible methods.

For certain adult categories, industry-specific standards apply. One example from the research is ISO 3533 for sex toys, which defines acceptable materials and safety-oriented design requirements. The lesson is not that every ecommerce brand needs to master every niche standard, but that you should actively ask: for this category, which standards govern safe materials and construction, and can my manufacturer show compliance?

You do not need ISO certificates framed on your office wall to benefit from standards. You do need to know they exist, ask your suppliers the right questions, and translate their assurances into concrete acceptance criteria for your own brand.

Defining Your Commercial Quality Standard

Before you can hold anyone to a professional-grade standard, you need to define what that standard is for each product line. Insight7 emphasizes that effective product assessment starts with clearly defined evaluation criteria aligned with business goals and stakeholder expectations. OMS Measure, writing in the context of pipe measurement, shows how vague quality expectations turn into disputes and failures, while clear specifications and tolerances enable objective evaluation.

A practical way to approach this for a personalized product line is to move from vague adjectives to measurable requirements.

Begin with the “job to be done” for the customer. A personalized tumbler needs to keep drinks at temperature for a reasonable period, survive daily handling, and preserve its print. A personalized baby blanket needs to be soft, safe for skin contact, and washable without shedding fibers or dyes.

Translate those expectations into measurable attributes. These can include fabric weight, colorfastness after a set number of wash cycles, print sharpness at typical viewing distance, edge smoothness on engraved items, and packaging integrity after transport. Where possible, borrow test methods from established standards; for example, ASTM’s performance specifications for various consumer products can inspire your own tests even if you are not yet certified.

Then define tolerances and acceptance criteria. OMS Measure uses frameworks like SMART and the “Target, Tolerance, Test” model. In ecommerce terms, this might mean deciding what percentage of minor print variation you will accept, how much packaging damage still counts as acceptable, and what level of color shift is within bounds for reprints.

To keep this concrete, consider a simplified view:

Attribute | Example Commercial Standard | How You Verify in Practice |

|---|---|---|

Print durability | Design must remain legible and unfaded after 20 wash cycles | Periodic wash tests on sample units from each production run |

Color accuracy | Colors within an agreed tolerance of original design | Compare printed samples to calibrated screen and reference swatches |

Safety for intended user | Materials compliant with relevant standards for age and use | Obtain supplier test reports and certifications; spot-check documentation |

Dimensional accuracy | Size within defined tolerance of advertised measurements | Measure random samples from batches |

Packaging and presentation | Arrives intact, with no exposed sharp edges or smudged prints | Pre-shipment inspection and monitoring of customer feedback |

Once you define your standards, you can embed them in product evaluation guidelines similar to those described by Insight7: define relevant criteria, ensure they are measurable, involve stakeholders such as customer support and design, and benchmark against internal and external references.

Practical Quality Practices for On-Demand Printing and Dropshipping

With standards defined, the next question is how to enforce them in an environment where you do not own the presses, warehouses, or trucks. The answer lies in building a lightweight but disciplined QA/QC system around your on-demand partners.

In pre-production, focus on design control. ComplianceQuest describes how manufacturers integrate product lifecycle management data with quality systems to improve design quality and traceability. In your business, this means standardizing how art files are created, stored, and approved. Set minimum resolution thresholds, lock color spaces, define acceptable print areas, and maintain version control so that when a defect emerges you can trace it back to a specific file, template, or change.

During production, introduce sampling and in-process checks. LP Centre and Factored Quality both argue for quality checks at multiple stages rather than relying solely on a final inspection. Even if your print partner runs the factory, you can negotiate sampling plans: for example, requiring that one out of a defined number of units per batch be inspected for alignment, color density, and defects, with clear documentation.

Calibration matters more than most ecommerce teams realize. ComplianceQuest and DELMIAWorks underscore the importance of calibrating measurement instruments and doing Gage Repeatability and Reproducibility studies so that readings are reliable. For digital printing and engraving, calibration translates into consistent printer profiles, regular maintenance, and verification that the same file printed at two sites yields indistinguishable results under normal conditions.

After production, invest in traceability and defect reporting. Factored Quality recommends labeling products with granular data such as production date and factory so you can trace defects back to specific runs or locations. While you may not control physical labels, you can embed this information in order metadata and require your suppliers to log batch identifiers.

Defect reporting should be structured, not anecdotal. When customer support receives a complaint, they need fields to classify it: product line, fulfillment location, type of defect, severity, and associated photos. Over time this dataset becomes your feedback loop for CAPA, the corrective and preventive action discipline described by ComplianceQuest. Instead of simply refunding orders, you identify root causes, implement preventive steps such as updated artwork guidelines or supplier changes, and monitor whether the issue recurs.

Partnering with Suppliers Without Losing Control of Quality

Most on-demand brands are only as strong as the worst factory in their network. That is why serious manufacturers, as described by ComplianceQuest and MachineMetrics, treat supplier quality management as a strategic imperative, not a procurement function.

Start by vetting manufacturers on more than price and catalog breadth. Factored Quality recommends evaluating suppliers on their experience with similar products, their ability to meet your quality standards, and their openness to audits and data sharing. Ask practical questions: what standards do they follow, how do they handle nonconforming products, what are their typical defect rates, and how do they train operators?

Define supplier quality requirements in writing. SafetyCulture and OMS Measure both stress the importance of clear requirements and documentation. For an ecommerce brand, this could take the form of a simple supplier quality agreement that spells out your expectations for product standards, sampling plans, response times on quality issues, documentation to be provided, and remedies for chronic underperformance.

Once a supplier is in your network, monitor performance with metrics. Ease highlights supplier defect rates, incoming quality levels, and chargebacks as common measures. Track each supplier’s share of total orders, their reported defect rates, your observed customer complaint rates, and on-time delivery. Use this data to adjust volume allocations, support suppliers who improve, and phase out those who cannot meet your standards.

Technology can bridge some gaps. MachineMetrics points out that connected machine data platforms make QC faster and more accurate by bringing defect detection closer to the point of production. While many small POD partners may not run such platforms, larger manufacturing partners will increasingly offer real-time dashboards. Where that is not available, push for at least periodic summaries of internal quality metrics and audit findings.

The cultural piece matters as much as the technical one. Continuous improvement resources highlight that when quality is seen as everyone’s job, rather than a small department’s, improvements stick. As a brand owner, you can reinforce this culture by sharing defect data transparently with partners, co-designing improvements, and recognizing suppliers when their quality metrics improve rather than only contacting them when something goes wrong.

Personalization, Quality, and the Customer Journey

One of the most powerful insights from Dataforest, SuperOffice, and OWD is that personalization and quality are not separate levers. They interact across the entire customer journey.

Personalization makes your relevance higher. Dataforest notes that a large majority of customers are willing to share behavioral data for smoother shopping if they trust the brand. SuperOffice reports that many customers feel frustrated by impersonal experiences. OWD’s research finds that rich previews, guided personalization options, and real-time feedback increase confidence and conversions.

However, personalization amplifies perceived defects. When customers co-create a product by selecting fonts, colors, and messages, the emotional investment is higher. A misaligned print, incorrect color, or poor-quality base product does not feel like a generic factory error; it feels like a broken promise. That is why OWD recommends setting clear customization guidelines and constraints, including character limits and visual examples of good and bad designs, combined with real-time feedback on legibility. Those guidelines are not just UX features; they are embedded quality controls.

There is also a data opportunity. Every personalization choice, preview, and subsequent rating is a data point you can feed back into both your recommendation systems and your quality evaluation. If a particular design layout consistently leads to higher complaint rates, that is a candidate for redesign or retirement. If customers who use certain customization features exhibit higher lifetime value, those features deserve more investment in robustness and testing.

Treat your personalization engine and your quality system as a single loop: recommendations drive purchases, quality experiences drive retention and more data, and the combined signals guide what products you offer and how you manufacture them.

Mini Case Scenario: Two Paths for a Personalized Brand

Consider two hypothetical brands selling personalized drinkware through on-demand fulfillment.

The first brand treats its supplier’s default catalog and processes as given. It uploads designs, runs ads, and lets orders flow. It reacts to complaints with refunds but does not log defect details beyond simple tags. Over time, it notices rising ad costs and flattening repeat purchase rates but cannot pinpoint why. Its social reviews mention inconsistent print quality, peeling designs, and occasional safety concerns around poorly finished edges.

The second brand uses many of the practices discussed here. Before launch, it defines a commercial standard for print durability and finish, informed by industry resources like ASTM and SafetyCulture. It works with a supplier that can provide test reports and agrees to basic sampling plans. It formalizes defect reporting in its helpdesk system, categorizes complaints, and reviews them monthly. It treats quality metrics such as reprint rates and quality-related returns as seriously as acquisition metrics.

When the second brand notices a spike in complaints tied to a specific color variant and fulfillment center, it initiates a root cause analysis in collaboration with the supplier. Together they discover a calibration issue in a new printer and correct it. Complaint rates fall, and they decide to increase volume to that center because it now shows higher consistency than others.

On the surface, both brands sell similar personalized products. Commercially, one operates at professional grade, with quality standards and practices that compound over time. The other is stuck in a cycle of guessing and discounting. The difference is not luck; it is quality management.

FAQ: Quality Standards for Personalized E-commerce Products

Do small ecommerce brands really need to care about standards like ISO or ASTM?

You probably do not need full certification to ISO 9001 in the early stages, but you do need to think in terms of standards. SafetyCulture explains that quality standards create uniformity and underlie good manufacturing practices. ASTM consumer product standards show how safety and performance are defined and tested in specific product categories. Even if you never file a certification, borrowing test methods and acceptance criteria from these standards will make your products more reliable and defensible if something goes wrong. Ignoring them does not exempt you from regulatory expectations; it only removes a valuable toolkit.

How can I enforce quality if I don’t own the factory?

You enforce quality by defining your standards clearly, selecting partners who can meet them, and using data to hold them accountable. ComplianceQuest and Factored Quality both emphasize supplier quality management, audits, and integrated systems as levers for maintaining control across organizational boundaries. In practical terms, insist on clear specifications, documented sampling plans, visibility into defect rates, and agreed escalation paths for nonconformances. Track each supplier’s performance and adjust volume, pricing, or relationships based on data rather than anecdotes.

What is the fastest way to tell if my personalized product line is “professional grade”?

A quick reality check is to look at three signals together: complaint and return rates, repeat purchase behavior, and the nature of your support tickets. If you see recurring quality-related complaints, higher returns for defects than for preference, and a large share of first-time customers never coming back, the market is telling you your products are not yet professional grade. Cross-reference this with internal data such as defect reports, supplier differences, and product-specific metrics. From there, apply the structured approaches outlined by Guide Technologies, Ease, and others: define standards, measure systematically, and prioritize root causes rather than one-off fixes.

Closing Thoughts

Professional-grade personalized products are not the result of luck, inspiration, or a clever ad. They are the outcome of deliberately applying proven manufacturing quality principles to the world of on-demand printing and dropshipping. The good news is that you do not have to reinvent those principles. By borrowing frameworks from leaders in manufacturing quality, adopting relevant standards, and building a simple but disciplined quality system around your personalized catalog, you turn quality from a hidden liability into a visible competitive advantage. In my experience mentoring ecommerce founders, that shift is often what separates a short-lived merch experiment from a durable, premium brand.

References

- https://www.cpsc.gov/Research--Statistics/Information-Quality-Guidelines

- https://store.astm.org/products-services/standards-and-publications/standards/consumer-product-evaluation-standards.html

- https://www.china2west.com/defining-quality-standards-a-guide-for-product-development-prototypes/

- https://dataforest.ai/blog/the-power-of-personalized-product-recommendations-understanding-implementing-and-optimizing-strategies

- https://www.factoredquality.com/resource/8-best-practices-to-increase-quality-control-in-manufacturing

- https://guidetechnologies.com/best-practices-for-improving-quality-control-assurance-in-manufacturing/

- https://insight7.io/key-product-evaluation-criteria-to-follow/

- https://www.linkedin.com/pulse/how-ensure-quality-control-personalized-pleasure-products-amos-mok-ntnoe

- https://lpcentre.com/articles/quality-control-best-practices-to-ensure-excellence-in-product-and-service

- https://www.machinemetrics.com/blog/quality-control-in-manufacturing