Personalized Pullover Hoodies: Create Your Custom Style

Personalized pullover hoodies are the workhorse of modern casualwear and one of the most reliable canvases for brand storytelling, community identity, and personal expression. Whether you’re launching a print‑on‑demand line, adding dropship-enabled merch to your store, or designing a one‑off gift, success hinges on getting the fundamentals right: the base fabric, the decoration method, the construction quality, and the care experience. In my work mentoring e‑commerce founders in the on‑demand space, the most resilient hoodie programs are the ones that pair design ambition with operational practicality. This guide blends firsthand observations with reputable garment-industry notes to help you choose wisely and build a hoodie offer that delights customers while surviving real-world washing, workouts, and wear.

What “Personalized Pullover Hoodie” Really Means

A pullover hoodie is a knit sweatshirt with a hood and no center zipper. Personalization spans print, embroidery, patches, labels, and even hand‑painted artwork. In on‑demand and dropshipping contexts, customization typically involves digital printing (DTG or DTF), screen printing for larger runs, sublimation on high‑polyester blanks, or embroidery for a premium, long‑lasting finish. Beyond decoration, the base garment—its fiber blend, knit type, and weight—determines comfort, longevity, color vibrancy, and how well your art reads from 3 ft away and after 30 washes. If you want fewer returns and better reviews, start with the blank and the intended use, then choose the decoration method to match.

Fabric Foundations: Choose the Right Base

The right fabric is the single biggest lever for comfort, print quality, and durability. Industry sources consistently point to cotton, polyester, and blends as the core hoodie materials, with knit structures like French terry, sweatshirt fleece, and jersey sitting at the center of everyday wear. Several notes from apparel manufacturers and materials guides converge on a few practical truths: cotton breathes and prints brilliantly, polyester dries faster and resists shape loss, and blends balance feel with performance. Warmth depends on knit structure and weight much more than fiber alone.

Fabric or Knit | Handfeel & Breathability | Warmth & Drying | Durability & Care | Print/Embroidery Fit | Typical Best Use |

|---|---|---|---|---|---|

Cotton (ringspun/combed) | Soft, breathable, skin‑friendly | Moderate warmth, slower to dry | Can shrink; pre‑shrunk preferred | DTG and screen prints look vivid | Everyday comfort, sensitive skin |

Polyester | Slicker hand, less breathable | Strong warmth per weight, fast dry | Shape/color retention, low shrink | Sublimation and heat transfers excel | Performance or wet/cold conditions |

80/20 cotton‑poly (cotton face) | Cotton‑forward feel with resilience | Moderate warmth, quicker dry than cotton | Better wash performance than 100% cotton | Excellent DTG on cotton face, embroidery friendly | Balanced daily wear |

65/35 cotton‑poly | Soft yet resilient | Moderate warmth, better color hold | Fewer wrinkles/pilling than cotton | Screen print/embroidery stable | All‑purpose uniform/merch |

50/50 cotton‑poly | Easy care and colorfastness | Moderate warmth, faster dry | Great shape retention | Screen print reliable; DTG varies | Volume programs and team wear |

French terry (loopback) | Smooth face, airy loops; breathes well | Moderate warmth, comfortable indoors | Easy care; moderate shrink if cotton | Screen print and embroidery work; stabilize as needed | All‑season layering, athleisure |

Sweatshirt fleece (brushed interior) | Plush, cozy interior | Higher warmth, slower dry | Durable knits; pilling varies by yarn | Screen print okay; embroidery needs backing | Cool‑weather comfort |

Microfleece (poly) | Light, soft, good airflow | Light‑to‑moderate warmth, quick dry | Strong abrasion resistance | Printing limited; embroidery best | Active layering |

Polar fleece (poly) | Very warm, lofty | Excellent insulation | Long‑wearing; bulkier | Often not ideal for ink; embroidery favored | Deep winter warmth |

Jersey knit | Stretchy, drapey, breathable | Light warmth | Can bag/pill over time | Prints fine; stabilize for embroidery | Lounge/casual, slimmer silhouettes |

Wool or wool blend | Premium warmth, breathes while insulating | High warmth without bulk | Careful washing needed | Embroidery OK on denser knits | Cold climate, premium lines |

Nylon shells or blends | Smooth, wind/water resistance | Varies; often used as outer shell | Highly durable | Limited print; embroidery patches | Weather‑resistant styles |

Several sources highlight practical constraints that matter at checkout. For example, many shops avoid printing directly on thick polar fleece because the loft disrupts ink coverage; embroidery is usually preferred for clean, durable results (Billoomi Fashion). When you need vibrant, color‑accurate prints, a high‑cotton face knit is often the safest path (Printful, Kavys Customs). If you prioritize shape retention and fast drying, higher polyester content wins; one popular reference notes polyester exhibits about 0.4% moisture regain, explaining its quick‑drying behavior compared to cotton’s high absorbency (Kavys Customs). Cotton can hold substantial moisture—up to several dozen times its weight—great for comfort but slower to dry; that property also explains why cotton feels heavier when wet.

Weight and Warmth: Talk in oz/sq yd, Not Just Feel

Customers sense weight, but merchants must actively spec it. For hoodie shoppers, midweight tends to wear best year‑round, and heavyweight reads premium and warm. A practical shorthand from campus housing guidance defines “thick” hoodies as those built on fabric weights above about 10 oz per sq yd, while fabrics under roughly 8 oz per sq yd often feel too light for cold weather (University of Arizona Housing). Converting common midweight guidelines, many everyday hoodies land around 7–9 oz per sq yd; cold‑ready fleece starts around 10 oz per sq yd and goes upward. Treat these as directional ranges, and always verify the blank’s actual spec sheet when sourcing.

Use/Climate | Target Weight | Suggested Fabrics |

|---|---|---|

Warm climates and indoor wear | About 6–7 oz/sq yd | Cotton jersey, lightweight French terry |

All‑season layering | About 7–9 oz/sq yd | Midweight French terry or sweatshirt fleece |

Cold climate or outdoor | About 10–13 oz/sq yd | Brushed fleece, polar fleece, wool blends |

Athletic/high sweat | Light‑to‑mid with fast‑dry behavior | Polyester or high‑poly blends, microfleece |

When decision makers press for a single “best” fabric, emphasize purpose. Cotton‑forward blends maximize comfort and print vibrancy; poly‑forward blends maximize performance and longevity. Market estimates on hoodie size vary widely, but that only strengthens the point: align fabric and construction to your customer’s lifestyle, not an abstract “best in class” trophy.

Fit, Construction, and Features That Matter

Materials only take you halfway. Construction determines whether your hoodie feels premium and survives embroidery, wash cycles, and tugging at the cuffs week after week. Consumer decision models commonly evaluate fiber content and weight, seam and hem quality, reinforcements at stress points, and consistent sizing. In practice, I advise founders to inspect seams at the shoulders and underarm, check for side‑seam twisting after a wash, look at the density of the knit, verify rib cuffs have recovery, and confirm drawcords and grommets feel secure. If your audience skews taller or layers jackets over hoodies, longline and relaxed cuts reduce returns. Expect some shrinkage with cotton‑heavy fabrics; pre‑shrunk and ringspun cotton helps.

Decoration Methods: Match the Art to the Fabric

All decoration methods are not created equal, especially on knits with pile or loft. Pick a method based on the fiber content, surface smoothness, run size, and the effect you want. The choices below consolidate guidance from production shops and apparel printers.

Method | Works Best On | Practical Notes |

|---|---|---|

Screen printing | Cotton and blends with smooth face | Durable and cost‑effective at volume; bold graphics shine. |

DTG (direct‑to‑garment) | High‑cotton or cotton‑face blends | Bright, soft prints with fine detail; pretreat and test darker shades. |

DTF (direct‑to‑film) | Cotton and blends | Versatile for small batches and color complexity; hand feel depends on film. |

Sublimation | High‑polyester content | Vivid, permanent designs; not for cotton; great for all‑over prints. |

Embroidery | Stable knits and fleece | Premium look; use proper backing on lofty fleece or stretchier jersey. |

Heat transfer/vinyl | Polyester and blends | Precise color/position; thicker hand; mind heat limits on decorated areas. |

Hand‑painted/fabric paints | Cotton and blends | Let paint fully cure before washing; cold‑wash; avoid the dryer (Angelus Direct). |

As a rule of thumb, use high‑cotton for the brightest DTG result and go high‑poly for sublimation. If you choose polar fleece for winter coziness, plan for embroidery or patches rather than ink-based prints, as many shops report uneven coverage on heavy loft. When in doubt, order pre‑production samples and wash‑test them, because the hand feel of films, pretreatments, and backings can vary across vendors.

Care and Longevity: Keep Hoodies Looking New

Great hoodies are engineered not only to feel good at unboxing but also to stand up to life. Care is a two‑part job—protect the garment and protect the design. The overlap across reputable print, apparel, and craft sources is clear: cold water, gentle handling, and low or no heat make custom pieces last.

For everyday washing, start by reading the garment’s label. Turn hoodies inside out to shield prints and embroidery, empty pockets, close zippers, and use a mild, color‑safe detergent. Cold water protects fibers and color vibrancy and reduces dye transfer. Gentle cycles and low‑to‑moderate spin help avoid stretching, especially around embroidery threads and seams. Air‑drying is kinder to both graphics and fibers; if you use a dryer, select the lowest heat and remove promptly to limit shrinkage and creasing (Veetrends, Kustomizey, RushOrderTees, OSS Apparel).

Embroidery deserves special attention. Wash inside out, treat it gently, and avoid ironing directly on stitched areas. If you must iron, skip steam and use a pressing cloth, or iron from the reverse side to prevent crushing and shine (Threadfellows).

Painted hoodies require curing discipline. Allow painted designs to cure fully before the first wash—many guides suggest several days, with low‑heat setting steps depending on the paint type. Wash in cold water with a gentle, fragrance‑free detergent, inside out, and avoid scrubbing the artwork. Air‑dry flat on a clean towel and never tumble dry; heat can soften or distort paint binders. If machine washing is unavoidable, a mesh laundry bag and a delicate cycle reduce risk, but handwashing is still safer (Angelus Direct).

Sublimated hoodies hold color inside the polyester fibers rather than on the surface. To preserve prints, avoid harsh chemicals, aggressive friction, and high heat. Cold water, gentle agitation, and air‑drying or low heat protect brightness and shape (Dasflow). Across all decorated pieces, steer clear of bleach and enzyme-heavy detergents; fabric softeners can weaken certain print adhesives and dull embroidery over time (Kustomizey, RushOrderTees, OSS Apparel).

Storage affects longevity more than most people realize. Fold along seams to limit pressure lines through prints, and hang heavier pieces on wide, padded hangers if needed. Keep garments away from heat and direct sunlight to reduce fading, and give them a bit of breathing room so knits don’t compress into permanent creases (OSS Apparel, Kustomizey).

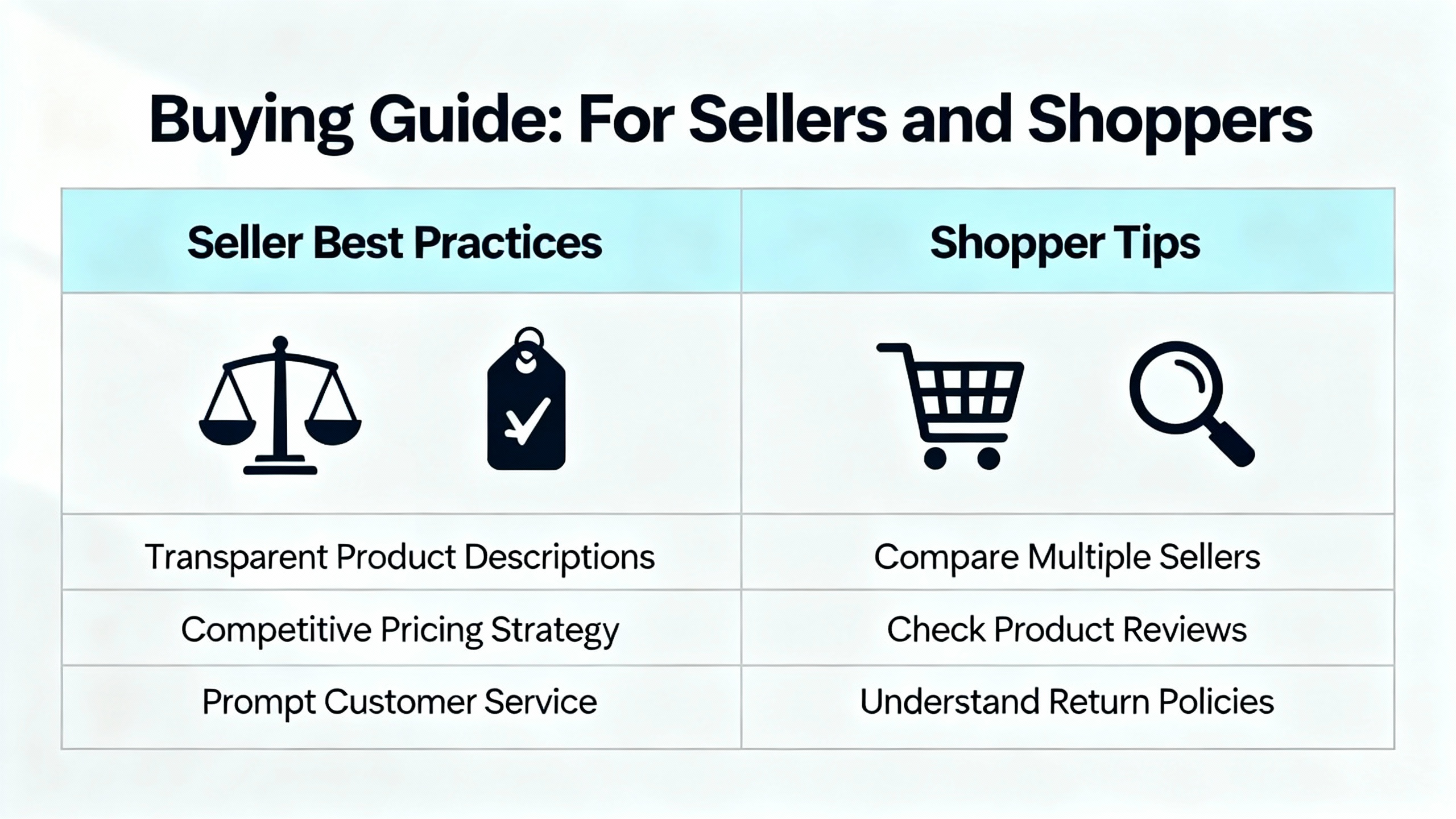

Buying Guide: For Sellers and Shoppers

If you’re sourcing for a store, choose blanks with a clear spec sheet showing fiber composition, knit type, and fabric weight in oz per sq yd. For cotton‑heavy blanks, look for pre‑shrunk or ringspun yarns to reduce shrink and pilling. If your graphic strategy relies on ultra‑vibrant prints, prioritize cotton‑face fabrics; if your audience demands fast‑dry, shape-retentive hoodies, increase polyester ratio. Test a small batch with your actual decoration method before committing. Review size charts carefully, because inconsistent fits drive returns; if your core buyer layers jackets, consider relaxed or tall cuts. Mind shipping weight; heavier fleece adds warmth and perceived value but costs more to ship, which matters during holiday spikes like Black Friday/Cyber Monday when free shipping thresholds get aggressive.

On the consumer side, focus on use case. For indoor lounge and everyday comfort, cotton or cotton‑forward blends feel best and print beautifully. For outdoor training or rainy commutes, polyester‑forward blends perform better and dry faster. If you run cold—or your winter really does feel like winter—brushed fleece around 10 oz per sq yd and up feels right. When caring for special art such as embroidery or paint, plan to wash cold and air‑dry; it’s the simplest way to add years to your hoodie.

Pros and Cons of Personalized Pullovers

Personalized pullover hoodies excel at brand storytelling and gifting because they present a large, comfortable canvas and a unisex fit. They convert well in on‑demand catalogs, and blanks are readily available in wide color runs and weights. With the right setup, DTG and DTF handle small orders without large minimums, and embroidery elevates perceived value. At the same time, knits complicate decoration because the surface is rarely as smooth as a T‑shirt; lofty fleece can resist ink, and the thicker the garment, the more you must stabilize embroidery. Cotton prints brilliantly but can shrink, and polyester resists shrinking but can retain odors if not laundered promptly. None of these are dealbreakers—just reasons to match fabric and decoration to the shopper’s actual life.

Sustainability Notes You Can Act On

If your buyers are eco‑conscious, consider organic cotton, recycled polyester, or newer cellulosics like lyocell in blends (Fabric Sight, Longan Craft). Recycled polyester gives a second life to plastic waste and maintains the moisture‑managing strengths of polyester; organic cotton reduces pesticide exposure in the supply chain. There are trade‑offs—natural fibers often feel better and print brighter, while synthetics last longer and dry faster—so be candid in product pages and let shoppers choose aligned to their values.

The Practical Takeaway

Personalization succeeds when you align three decisions: pick a base fabric that feels right in its intended climate, match your decoration method to that fabric, and give clear care instructions that protect both garment and design. Cotton‑forward for comfort and vivid prints, poly‑forward for performance and longevity; French terry when you need airflow, brushed fleece when you need warmth. If you stick to cold water, gentle detergent, and low or no heat drying, your customers will keep wearing—and showing off—your hoodies for seasons, not weeks.

FAQ

What hoodie weight should I choose if I want something warm but not bulky? A mid‑to‑heavy brushed fleece around 9–10 oz per sq yd balances warmth and comfort without feeling rigid. If you’re layering under a coat, a denser French terry around the higher end of midweight can also feel warm while breathing better indoors.

Which fabric takes the brightest prints for detailed art? High‑cotton or cotton‑face knits generally deliver the most vivid DTG and screen prints. If you need all‑over prints or extreme colorfastness, choose high‑polyester and use sublimation instead, accepting a different hand feel.

Is polar fleece a good canvas for printing? Polar fleece is excellent for warmth but its lofty surface disrupts ink laydown. Many manufacturers steer decoration toward embroidery or patches on this fabric for clean edges and long‑term durability.

How should I wash a hoodie with embroidery or custom paint? Turn it inside out, wash in cold water with a gentle detergent, and air‑dry. Avoid steam and direct heat on embroidery; use a pressing cloth if you must iron. For painted hoodies, allow full curing before the first wash, and skip the dryer to prevent cracking or softening of the paint binders.

What’s the best all‑purpose blend for everyday custom hoodies? Blends like 65/35 or 80/20 offer cotton’s comfort with polyester’s resilience. If your art relies on vibrant, soft prints, an 80/20 with a cotton face is a strong everyday choice. If rugged laundering and color retention matter most, shift toward 50/50 or higher polyester.

How do I choose a decoration method for small runs? For small, design‑rich batches on cotton‑forward blanks, DTG or DTF handle detail without minimums. If your blank is high‑polyester and you want the most permanent color, sublimation is compelling. For a premium look that ages well across fabrics, select embroidery and stabilize the garment properly.

References

Publisher/Source | Key Contribution |

|---|---|

Affix Apparel | Hoodie fabric types and functional guidance on cotton, fleece, nylon, and sweatshirt knits. |

Kavys Customs | Material trade‑offs, common blend ratios (50/50, 65/35, 80/20), cotton absorbency, and polyester moisture behavior. |

Fabric Sight | Fabric weights by knit type and sustainability considerations for athleisure. |

Longan Craft | Comprehensive hoodie fabric guide, fleece variants, and blend insights for warmth and durability. |

Billoomi Fashion | Practical notes on fleece printing limits and cotton loopback/French terry use in hoodies. |

Gelato | Plain‑language framework for choosing by breathability, warmth, durability, comfort, and style. |

University of Arizona Housing | Thickness benchmark; “thick” hoodies typically above about 10 oz per sq yd. |

Angelus Direct | Hand‑painted hoodie care: curing, cold wash, no tumble dry, and gentle detergents. |

Dasflow | Sublimated hoodie care: protect against heat, chemicals, and abrasion; favor cold, gentle cycles. |

Threadfellows | Embroidery care: wash inside out; avoid steam; use a pressing cloth or iron from reverse. |

Kustomizey | Maintenance habits to preserve customized hoodies: cold wash, air‑dry, sun avoidance, storage tips. |

OSS Apparel | Care for custom printed apparel and method compatibility across print technologies. |

Veetrends | Hoodie wash guidance: label‑first, cold water, gentle cycles, low heat or air‑dry. |

RushOrderTees | Care for custom prints and common failure modes; protect graphics and garments with low heat and gentle handling. |

Printful | Hoodie materials, customization rules, tri‑blend insights, cotton‑face guidance, and knit construction notes. |

The/Studio | Fabric selection overview and market context; projections vary widely across sources. |

If you need help translating this framework into product pages and supplier briefs—or want a short checklist for sample testing and wash‑proofing—say the word and I’ll share templates tailored for on‑demand and dropship workflows.

- https://dev.housing.arizona.edu/best-thick-hoodies

- https://combatvets.socialwork.msu.edu/old-navy-hoodies-mens

- https://cannon.tennessee.edu/wp-content/uploads/sites/85/2020/04/4H-Judging-CDM-Study-Hoodies.pdf

- https://www.billoomifashion.com/post/which-fabric-should-i-choose-for-hoodies-sweatshirts-collection-ultimate-guide

- https://www.dasflow.com/blogs/how-to-care-for-your-sublimated-hoodie-tips-and-tricks

- https://www.gelato.com/blog/hoodie-material

- https://kustomizey.com/blog/expert-tips-for-maintaining-your-customized-hoodies

- https://www.melengo.com/post/best-hoodie-materials-which-fabrics-should-you-choose

- https://oss-apparel.com/ultimate-care-guide-for-your-custom-printed-apparel/

- https://www.printful.com/blog/best-hoodie-materials