Heavy Duty Custom Bags: Reinforced Carriers for Maximum Durability

Heavy duty custom bags sit at an interesting crossroads in modern commerce. They are part packaging, part equipment, and part mobile billboard. In the on-demand printing and dropshipping world, they can quietly become one of your highest lifetime value product categories if you design them correctly. In my work with ecommerce founders, the biggest missed opportunity I see is treating “tote bags” and “gear bags” as generic add-ons instead of engineered, durable tools that customers come to depend on.

In this article, we will look at heavy duty custom bags through a practical, operator’s lens. We will ground every recommendation in what manufacturers, armor experts, and industrial packaging companies are already doing in real-world harsh conditions, and then translate those lessons to your print-on-demand and dropshipping strategy.

What Counts as a Heavy Duty Custom Bag?

A heavy duty custom bag is more than a canvas tote with a logo. It is any reinforced carrier designed to handle high loads, rough handling, or harsh environments while also carrying branding or personalization.

At one end of the spectrum, you have industrial-strength work bags like the oilfield duffels described by Bad Ass Work Gear. These bags are marketed as “the only oilfield bag you’ll ever need” and are trusted by oilfield workers, truckers, firefighters, and even members of the U.S. Armed Forces. They survive daily punishment in places ranging from the Canadian tundra to the heat and salt of the Gulf of Mexico, and they come in multiple sizes and colors to balance capacity with user preference.

On the softer side, there are heavy duty moving and storage totes such as the Rugged Rhino bags sold on Amazon-like marketplaces. Each bag is rated around 50 lb, with a waterproof, puncture-resistant shell and reinforced handles. These are optimized for bulky textiles and repeated moving or seasonal storage, not for sharp tools or industrial chemicals.

Then there are heavy duty poly shipping bags from companies like PolyPak and APlasticBag. These large polyethylene bags carry fertilizers, garden compost, wood pellets, decorative rock, and similar materials. They rely on coextruded multilayer films, UV-inhibiting additives, and high impact and puncture resistance to survive outdoor storage and palletized shipping, while providing full-wrap custom printing for branding.

Finally, in the tactical and safety world, plate carriers function as extreme load-bearing bags for armor and gear. Primary Arms, Premier Body Armor, RMA Defense, and Spartan Armor Systems all stress that a plate carrier must carry at least 8–10 lb of armor and can easily reach roughly 20 lb or more once ammunition, communications, and sustainment gear are added. These carriers are built from rugged nylon and Cordura fabrics with reinforced stitching, MOLLE or laser-cut attachment panels, and quick-release systems. They are a reminder that for some customers, a “bag” is literally life-support equipment.

For a serious ecommerce operator, all of these examples belong under the heavy duty custom bag umbrella. The common denominator is engineered durability plus meaningful customization.

Durability as a Profit Center, Not Just a Feature

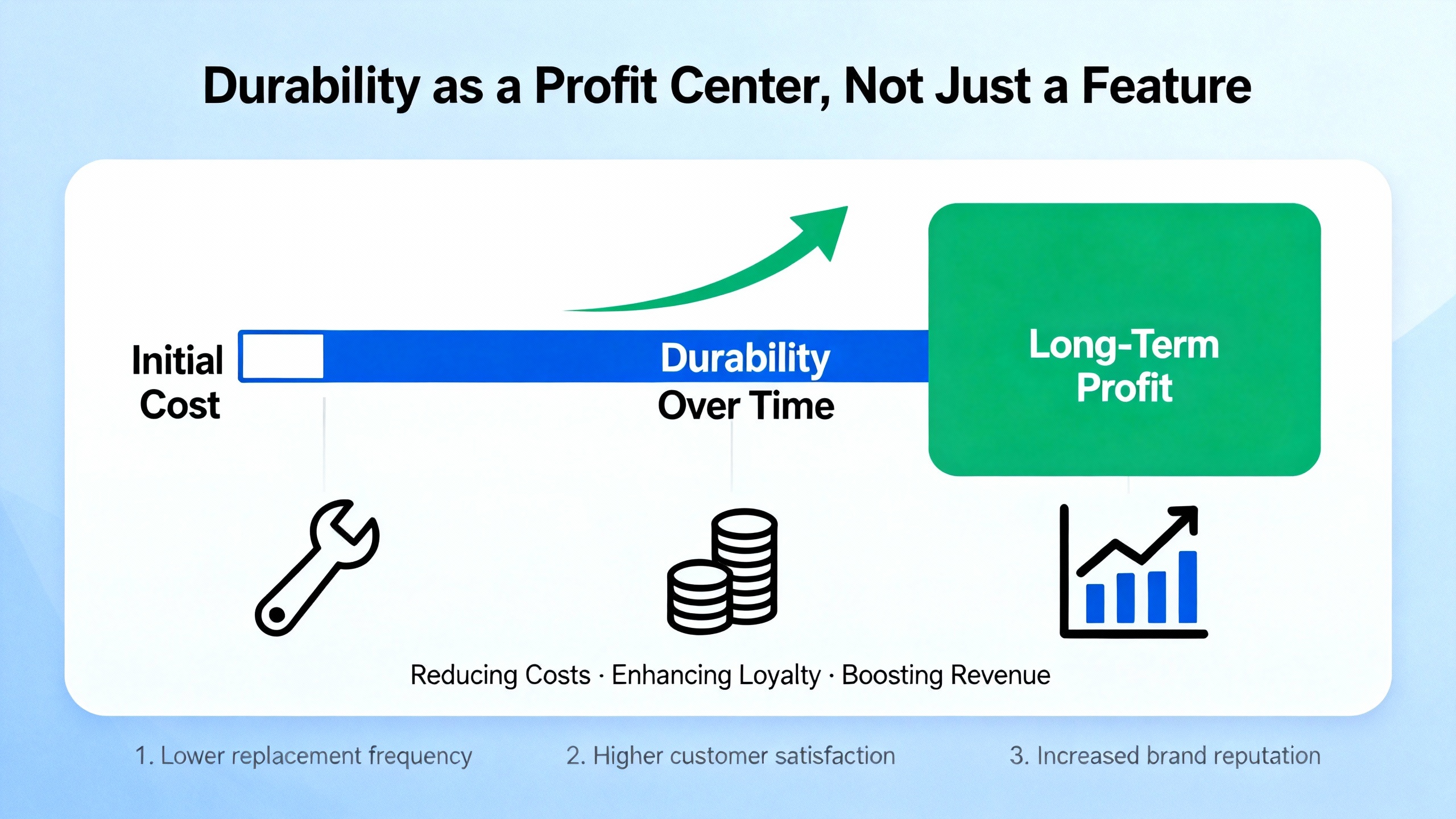

Most founders intuitively understand that durable products are “good.” The more useful framing, though, is that durability is a profit center.

Promotional marketing specialists like ePromos point out that quality promotional tote bags can generate up to about 5,900 brand impressions over their lifetime and that roughly 31 percent of U.S. households use custom tote bags regularly. When you put your logo on a well-made heavy duty bag, you are buying thousands of low-cost impressions over years, not days. Weak materials that fray, tear, or fail at the handles turn that investment into a complaint and a lost customer instead.

Bag and material specialists such as ToteBagFactory and QualityImprint repeatedly emphasize that thick canvas, tightly woven recycled polyester, and higher-grade nonwoven materials significantly increase a bag’s lifespan. They describe well-made canvas and nylon totes as “walking billboards,” precisely because customers keep them in rotation far longer than flimsy plastic or thin fabric bags.

This is equally true in the tool and tactical segments. UniversePack, in its guide to tools bags, notes that upgraded materials like Cordura nylon and reinforced stress points at handles, corners, and seams are what separate long-lasting gear bags from disposable ones. Armor brands like Primary Arms and RMA Defense echo the same principle when they advise buyers to favor reputable brands, reinforced stitching, and appropriate nylon or denier materials in plate carriers.

From a financial standpoint, every step up in construction that extends real-world lifespan reduces cost per use, reduces returns, and increases the odds that your bag becomes part of a customer’s daily routine. That recurring use is where referrals, user-generated content, and recurring orders start to show up.

Core Use Cases and Buyer Personas

When you design a heavy duty bag line, you are not designing “for everyone.” Each niche has its own abuse patterns and expectations.

Industrial and field professionals resemble the oilfield workers targeted by Bad Ass Work Gear or the contractors buying rugged tool bags from brands like Rhino USA. They want duffels and tool bags that survive gravel, salt, freezing weather, and being thrown into the back of a truck. For them, features like abrasion-resistant bases, strong hardware, and reliable zippers matter more than fashion colors.

Tactical users and first responders are closer to the plate carrier crowd described by Premier Body Armor, RMA Defense, and Spartan Armor Systems. They need carriers and bags that hold armor plates, ammunition, medical gear, and communications equipment, all while balancing weight across the torso and remaining comfortable under long wear. For this group, modularity, adjustability, and proven materials such as rugged Cordura fabrics and high-denier nylon are non-negotiable.

Retail and promotional buyers are often focused on heavy duty tote bags. Paper Mart’s custom heavy duty totes, for example, use premium nonwoven polypropylene with reinforced handles and gusseted sides. These bags are intended for retail presentation, gift giving, and reusable grocery use. Promotional platforms like ePromos highlight the ability to choose materials, sizes, and features to match brand identity and budget, from affordable nonwoven totes to higher-end canvas and boat totes.

There is also the environmentally conscious consumer. The canvas bag overview from Sewing-Contractors notes that canvas bags can meaningfully reduce plastic waste if reused at least 50 to 100 times. For this audience, organic cotton, recycled canvas, and eco-friendly dyes become part of the value proposition. They will scrutinize sustainability claims, but if your bag holds up for hundreds of uses, they are more likely to become brand evangelists.

Clarifying which of these personas you are actually serving will shape every decision you make about materials, structure, customization, and pricing.

Material Choices for Heavy Duty Custom Bags

Material is the foundation of durability. The research across tool bags, tote bags, poly bags, and body armor points to a relatively small set of proven workhorses.

Canvas and Heavy Cotton

Canvas is a densely woven cotton fabric that has historically been used for sails, tents, and awnings. Sewing-Contractors describes canvas bags as reusable carriers crafted from sturdy woven cotton, valued for high tensile strength and the ability to withstand daily wear and tear. They are particularly suited to heavy grocery loads, books, and everyday essentials.

ToteBagFactory recommends heavy-weight cotton canvas around 12 oz or higher for superior durability. This heavier canvas helps the bag hold its shape, resist stretching and tearing, and safely carry heavier items such as laptops or bundles of documents. An Amazon wholesale canvas tote cited in the research measures roughly 15 in wide by 16 in high by about 3 in deep, with a bottom gusset that increases capacity and helps the bag stand more easily. The combination of sturdy canvas and structured bottom gusset offers better load-bearing capacity than flat, unstructured totes.

Canvas is ideal for custom printing and embroidery. It accepts screen prints, heat transfers, and stitched designs cleanly, and the natural texture supports a premium look. The downside is that untreated canvas absorbs water and can mildew in damp environments. For heavy duty outdoor use, a waxed or coated canvas treatment, mentioned in the canvas and cleaning guides, improves water resistance.

From a sustainability standpoint, canvas made from 100 percent cotton is biodegradable and can be recycled through textile programs. That makes it particularly attractive for brands positioning themselves as eco-conscious.

Nonwoven Polypropylene and Polyester

Heavy duty tote lines from Paper Mart and ePromos show that nonwoven polypropylene (often abbreviated NWPP) is the dominant synthetic material for reusable totes in the promotional market. Paper Mart’s “custom heavy duty canvas totes” are, in fact, made from 100 GSM premium nonwoven polypropylene that is degradable, recyclable, and cold-wash only. ePromos describes one of its popular shopping totes as made from heavy-duty 80 g nonwoven polypropylene with reinforced handles.

Nonwoven polypropylene is lighter than canvas, resists moisture, and is inexpensive at scale. It is particularly suitable for retail, event, and trade show bags where budget matters but you still need a bag that will last many uses. Polyester and recycled polyester are also common, especially in sleeker, more water-resistant designs. QualityImprint notes that tightly woven recycled polyester or PET can produce durable promotional totes that resist stretching and tearing better than thin polyester.

The trade-off is environmental. Synthetic fibers are less biodegradable than cotton or jute. That is why brands with a strong sustainability story often favor organic cotton, canvas, jute, or recycled fabrics, even if nonwoven polypropylene and polyester might be cheaper.

Industrial Poly Bags for Bulk Products

If your customers are in lawn and garden, agriculture, or bulk materials, you will encounter heavy duty poly bags rather than fabric totes.

PolyPak describes heavy duty poly bags as large, durable plastic shipping bags made from strong polyethylene films specifically designed to hold fertilizers, sand, garden compost, mulch, wood pellets, potting soil, seeds, and decorative rocks. Their coextruded multilayer polymer films are waterproof and resistant to punctures and tears. Key performance features include strong sealability, UV inhibitor protection, chemical resistance, and customizable sizes and colors.

APlasticBag’s lawn and garden bags add more detail. These outdoor storage bags use materials developed to withstand harsh elements and include UV protection film that preserves both bag performance and printed graphics for up to six months. They emphasize extreme impact strength, excellent puncture resistance, high sealability, and low creep or stretch. Fade- and scratch-resistant inks allow full wrap-around prints, making the packaging itself a long-lasting marketing surface even when bags are palletized outdoors.

If you intend to sell or private-label such bags, understand that you are effectively entering the industrial packaging space. Your value is not just in printing a logo but in specifying film thickness, UV protection, and sealing performance that match the weight and storage conditions of your customer’s product.

Tactical and Tool Bag Fabrics

For tool bags, tactical packs, and plate carriers, performance fabrics dominate.

UniversePack highlights canvas, nylon, Oxford fabric, polyester, leather, Cordura, and denim as eight common materials for custom tool bags. Nylon is praised for being lightweight, strong, abrasion-resistant, and naturally water-resistant, especially in higher deniers. Oxford fabric, usually a polyester or polyester–cotton blend, offers affordable ruggedness for light to moderate use. Cordura, a high-performance nylon, stands out for superior abrasion, tear, and scuff resistance—ideal for demanding environments such as construction or fieldwork and for carrying sharp, heavy tools. Leather adds a premium look with strong durability and impact protection but at the cost of higher weight and required maintenance.

Tool bag brands like Rhino USA lean into this space by emphasizing premium, durable materials and reinforced interiors that organize and protect tools across garages, worksites, camping trips, and off-road adventures.

Tactical plate carrier makers, according to RMA Defense and Primary Arms, typically use rugged Cordura fabrics with reinforced stitching and MOLLE or laser-cut webbing panels. These carriers must support the combined weight of plates and gear without failure, which is why high-quality fabrics, heavy-duty thread, and reinforced stress points are repeatedly highlighted as vital.

The lesson for ecommerce sellers is straightforward. If your bag is expected to carry metal tools, armor plates, or other dense loads, treat Cordura, high-denier nylon, or reinforced canvas as your baseline and inspect stitch patterns and hardware with the same seriousness that armor brands bring to their carriers.

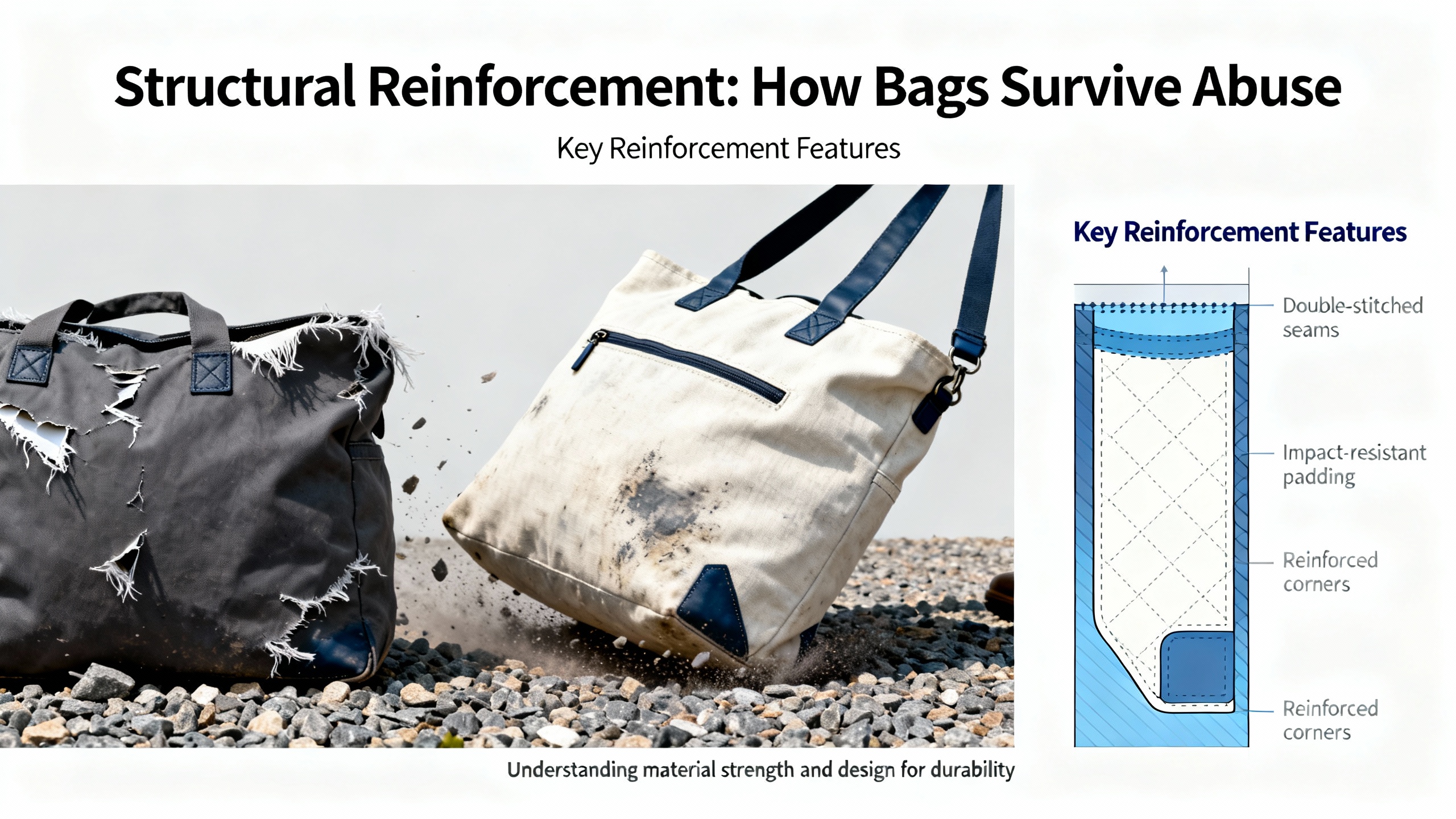

Structural Reinforcement: How Bags Really Survive Abuse

Material alone does not make a bag heavy duty. Structure and reinforcement determine whether it fails at the seams or survives another year.

Paper Mart’s heavy duty tote bags illustrate this well. They feature stitched handles for durability, spacious gusseted sides for more capacity, and a plastic insert to maintain structure. That combination spreads load across seams, reduces stress on any single stitching line, and prevents sagging. It is a low-tech but effective way to extend service life.

UniversePack stresses reinforced stress points in tool bags, such as handles, bottoms, corners, and seams, and recommends heavy-duty zippers and water-resistant coatings for bags that will see frequent use or encounter moisture. Without these, the best fabric in the world can still fail where the user grabs and lifts.

Industrial poly bag producers solve a similar problem in a different material. APlasticBag emphasizes high sealability and low creep or stretch in their heavy-duty lawn and garden bags to prevent seals from opening and bags from deforming during stacking and long-term storage. PolyPak relies on coextruded multilayer films that resist punctures and tears while maintaining strong seals.

Rugged work bag makers like Bad Ass Work Gear demonstrate the end state: industrial-strength bags that can be thrown around oil rigs, trucks, and offshore platforms daily. While they do not detail their stitch count in marketing copy, the ability to survive such environments implies triple-stitched seams, reinforced handles, and heavyweight hardware.

In tactical plate carriers, Premier Body Armor and Primary Arms call out padded shoulder straps, wide cummerbund adjustment ranges, and reinforced construction as critical for comfort and durability. When a carrier is loaded to 20 lb or more, any weak seam or buckle becomes a failure point that can literally risk a life.

For your own product selection, ask suppliers not only what fabric they use, but how handles are attached, how bottoms are reinforced, what zippers and hardware are specified, and what failure modes they test for. When you are selling to heavy users, these details are your reputation.

Design and Customization for Branding

Durability keeps a bag in circulation. Design is what turns that longevity into marketing impact.

Promotional experts at ePromos describe custom logo tote bags as an ideal promotional product that maximizes brand exposure while replacing wasteful single-use plastic bags. Totes offer large imprint areas, are available in multiple materials and colors, and can be tuned from budget bags to premium carryalls. Pricing can range from under one dollar per bag for large-run nonwoven totes up to around two hundred dollars per bag for premium styles, allowing brands to match investment level to recipient value.

ToteBagFactory highlights canvas, cotton, jute, and recycled polyester as core materials for custom totes and emphasizes that high-quality materials produce more professional-looking bags that last longer and deliver higher return on investment than cheaper, thin alternatives. Well-made totes are more likely to be retained and used after events, extending the promotional lifespan.

On the customization process side, Paper Mart’s online design studio is a good example of how to make artwork integration predictable. Customers select a tote, enter the design studio, create or upload artwork, position it, review a proof, and then check out. There are strict artwork requirements: a single solid-color file in SVG, PDF, or EPS format under a given file size, with all uploaded artwork automatically converted to black before the customer selects ink color. The company charges a one-time silkscreen plate fee per artwork and explains that any artwork modification requires a new plate. Production begins only after artwork approval, which typically happens within 48 to 72 business hours, and all custom sales are final.

This level of transparency about the print process is exactly what I recommend ecommerce sellers emulate in their product pages and FAQs. When customers understand what is possible, what file formats you accept, what the limitations are (for example, single-color printing on some bags), and what the timeline looks like, you reduce friction and prevent costly back-and-forth.

For on-demand and dropshipping operators, there is another design decision: whether to work with blank base bags or preprinted stock. Amazon’s wholesale blank canvas tote, described as a sturdy, gusseted bag explicitly marketed as suitable for painting, printing, and embroidery, illustrates the blank approach. You can stock a handful of high-quality blanks and layer your designs on top. Alternatively, with industrial poly bags like those from PolyPak or APlasticBag, customization is typically integrated at the manufacturing stage, with full-wrap prints and colored films designed specifically for each customer’s product line.

Both approaches can work. The key is to understand your minimum order quantities, the flexibility you need in design, and how fast your catalog turns.

Lessons from Tactical Plate Carriers: Load, Fit, and Modularity

Even if you never sell body armor, the plate carrier world offers useful design lessons for heavy duty bag entrepreneurs.

Primary Arms and Premier Body Armor define a plate carrier as a modular, scalable armor vest that carries ballistic plates and gear. Proper setup balances protection, comfort, mobility, and even weight distribution front, back, and sides. Heavier items are placed centrally and close to the body to maintain stability, while shoulder areas are kept clear to avoid interfering with shouldering a rifle or accessing pouches.

The core components of a plate carrier are plate bags, shoulder straps, and a cummerbund or side straps, all of which must be adjustable. Fit is paramount. Users are advised to size armor plates to their torso first, then choose a carrier matched to plate dimensions. Plates should cover the “cardiac box,” running from about two fingers below the collarbone to around the base of the rib cage, instead of being worn low to protect the stomach.

From a durability standpoint, armor brands stress that a carrier must be robust enough for at least 8–10 lb of armor and often approximately 20 lb of load once magazines, communications gear, and sustainment items are added. Buyers are told to prioritize reputable brands, reinforced stitching, appropriate nylon or denier materials, and quality construction over purely aesthetic features.

Modularity is another key theme. RMA Defense and Premier Body Armor mention MOLLE webbing, laser-cut panels, placard-attachment systems, and swappable cummerbunds that enable users to reconfigure their loadouts for different missions. This is a pattern your heavy duty bag design can borrow. For example, you might incorporate MOLLE-style panels or attachment loops on a tool tote or range bag to allow customers to add pouches over time, increasing the product’s relevance and lifespan.

If your catalog directly includes plate carriers or armor-adjacent bags, you must also be aware of legal constraints. Premier Body Armor and Safe Life Defense note that civilian body armor ownership is generally legal for law-abiding citizens in most U.S. states, but convicted felons are prohibited, and states like Connecticut and New York impose specific restrictions, such as requiring in-person sales or limiting civilian possession. If you operate in this space, you should encourage customers to consult local laws and make sure your own sales policies respect those boundaries.

The broader takeaway is that when a bag or carrier is mission-critical, customers think in terms of trust, not fashion. Align your product selection and copy with that mindset whenever you serve similar segments.

Operational Considerations: Shipping, Returns, and Product Lifespan

High-durability bags are heavier, and weight influences both shipping and user comfort.

Safe Life Defense notes that individual armor plates can weigh from roughly half a pound to about 13.7 lb depending on material, thickness, and coverage. A typical full setup with two plates weighs around 15 to 35 lb, and a soldier’s plate carrier system is cited at around 22 lb. While tote bags usually do not reach those weights, the principle is the same. A dense canvas or leather tool bag with metal hardware can quickly become heavy when loaded. As a seller, you should list approximate bag weights in your product details and encourage customers to consider the total load, not just capacity in abstract.

Lifespan and warranties are another overlooked area. Safe Life Defense explains that all body armor degrades and that soft armor typically has a lifespan of about five years, while some hard armor can last 15 to 20 years when stored properly. While most heavy duty bags are not life-saving equipment, it is still helpful to understand and communicate realistic lifespan expectations. APlasticBag’s six-month UV protection claim for outdoor lawn and garden bags is a good example: the company makes a clear, time-bound promise about how long fade-resistant inks and UV-resistant film will maintain performance under outdoor exposure.

Cleaning and maintenance guidance can significantly extend a bag’s useful life and reduce support tickets. Sewing-Contractors recommends machine washing most canvas bags in cold water with mild detergent and air-drying them, while spot cleaning minor dirt with a damp cloth. RMA Defense suggests cleaning plate carriers by avoiding high heat and harsh chemicals, instead using a damp cloth and mild soap. UniversePack advises inspecting seams, zippers, and hardware regularly, especially on tool bags used in rough environments.

Ecommerce operators should incorporate similar guidance in product descriptions, packaging inserts, or post-purchase emails. Customers who know how to care for their bags will get more value, and you will see fewer premature “defect” claims that are really maintenance issues.

A Practical Framework for Choosing Heavy Duty Custom Bags for Your Store

Putting all of this together, you can use a simple sequence to decide which heavy duty bags belong in your lineup and how to position them.

First, clarify the primary use cases you want to serve. Are you focused on reusable shopping and lifestyle totes, industrial lawn and garden packaging, tool and equipment bags, tactical carriers, or a mix of these? It is better to own one or two niches deeply than to scatter across all of them superficially.

Second, choose materials that match those use cases. For eco-forward lifestyle brands, heavy canvas, organic cotton, and jute will align with customer values, as suggested by the canvas and tote bag guides from Sewing-Contractors and ToteBagFactory. For bulk product packaging, follow PolyPak and APlasticBag’s lead with multilayer polyethylene films that offer puncture resistance, UV protection, and strong sealability. For tool and tactical applications, consider Cordura, high-denier nylon, or reinforced canvas as highlighted by UniversePack, RMA Defense, and Primary Arms.

Third, evaluate structural reinforcement and hardware. Ask how handles are attached, whether there are gussets and inserts for structure, and what type of zippers and buckles are used. Use Paper Mart’s gusseted totes with plastic inserts and UniversePack’s recommendations for reinforced stress points as baseline standards, not nice-to-haves.

Fourth, design your customization strategy around both branding and operational simplicity. Decide where you will offer full-color prints, where single-color silkscreen is sufficient, and where embroidery adds enough perceived value to justify higher prices. Leverage platforms and supplier tools similar to Paper Mart’s design studio to standardize file formats and approval workflows, reducing friction and misprints.

Finally, model profitability with lifespan in mind. Use the promotional data from ePromos as a reference point: if a durable tote can deliver thousands of impressions, you can justify a higher landed cost and still enjoy a strong return. Similarly, if an industrial poly bag or tool bag dramatically reduces failure rates and customer complaints compared with cheaper alternatives, the long-term savings in reputation and support can outweigh slightly lower margins on each sale.

Material Comparison Snapshot

To make material selection more concrete, here is a concise comparison of some commonly used heavy duty bag materials drawn from the research.

Material | Typical Use Cases | Key Strengths | Primary Limitations |

|---|---|---|---|

Heavy cotton canvas | Reusable totes, fashion-forward bags, light tool carry | High tensile strength, print-friendly, biodegradable | Absorbs water, can mildew without treatment |

Nonwoven polypropylene | Promotional shopping totes, trade show bags | Lightweight, affordable, moisture resistant | Less eco-friendly, lower perceived luxury |

Recycled polyester / PET | Branded totes, travel bags | Durable, more water resistant, supports bold prints | Synthetic, recycling options vary by region |

Cordura nylon | Tool bags, tactical packs, plate carriers | Superior abrasion and tear resistance | Higher cost, can feel stiff without design care |

Leather | Premium tool bags, executive totes | High durability, impact protection, premium image | Heavy, requires conditioning and care |

Multilayer polyethylene film | Lawn and garden bags, bulk product packaging | Puncture and tear resistance, strong sealability | Limited reuse, plastic disposal considerations |

This table is not exhaustive, but it reflects the trade-offs manufacturers and brands already navigate in the real world.

Frequently Asked Questions about Heavy Duty Custom Bags

How many times should a heavy duty canvas bag be reused to be truly eco-friendly?

The canvas bag research summarized by Sewing-Contractors notes that studies suggest a canvas bag should be reused at least 50 to 100 times to offset the environmental impact of producing it when compared with single-use alternatives. In practice, well-made canvas totes with reinforced seams and quality printing can easily reach hundreds of uses if cleaned and stored properly. As a seller, you can help customers reach that benchmark by choosing heavy fabrics, specifying strong stitching and handles, and providing clear care instructions.

How long will branding last on outdoor heavy duty poly bags?

APlasticBag reports that its custom lawn and garden poly bags use UV protection film and fade-resistant inks engineered to remain a strong marketing tool for a minimum of six months in outdoor storage. That means logos and messages should remain legible and relatively vibrant through at least one typical outdoor season. If your buyers keep bags exposed longer than that, it is prudent to temper expectations and emphasize that prolonged sun and weather exposure will gradually degrade any print.

Are heavy duty bags worth the higher upfront cost for promotional use?

Promotional specialists such as ePromos argue that they are. When a custom tote bag can generate up to approximately 5,900 impressions over its lifespan and one-third of households use custom totes regularly, even a more expensive heavy duty bag can have a very low cost per impression. ToteBagFactory adds that better-made totes are retained and used longer than cheap giveaways, which extends your campaign’s reach. In simple terms, paying more for a bag that lasts years often delivers better return than buying the cheapest option that fails after a few uses and ends up forgotten in a closet or landfill.

What legal issues should I consider if I sell plate carriers or armor-related bags?

Premier Body Armor and Safe Life Defense both emphasize that body armor is generally legal for law-abiding civilians in most U.S. states, but there are important exceptions. Convicted felons are prohibited from buying or using body armor such as vests and plate carriers, and some states impose additional restrictions. For example, Connecticut requires face-to-face sales for most armor purchases, and more recent New York rules restrict certain civilian armor shipments. If your heavy duty catalog includes plate carriers or armor-adjacent products, you should clearly communicate that buyers are responsible for knowing their local laws and consider implementing basic screening or shipping limitations that reflect current regulations.

Heavy duty custom bags reward founders who think long term. When you specify the right materials, insist on proper reinforcement, and pair all of that with thoughtful customization, you are not just selling a bag. You are putting your brand into your customer’s daily routine, whether that is a grocery run, a weekend project, or a long shift in harsh conditions. Treat these products with the same seriousness that oilfield riggers, tool manufacturers, and armor makers bring to their gear, and they can become some of the most trusted and profitable items in your entire ecommerce catalog.

References

- https://badassworkgear.com/

- https://www.4allpromos.com/category/heavy-duty-tote-bags?srsltid=AfmBOorJi2PEQSfpSaXihz8g0C9HPWksL7e-ATeUif-85iXb23HA6tPZ

- https://www.aplasticbag.com/custombags/custom-heavy-duty-bags?srsltid=AfmBOoo8ud2x289ofyWYAoNmXab-xeaXFLfap1h_TOaOadCw1vlGrOLy

- https://smart.dhgate.com/affordable-and-reliable-plate-carriers-as-discussed-in-the-best-plate-carriers-reddit/

- https://www.rhinousainc.com/products/heavy-duty-canvas-tool-bag?srsltid=AfmBOoot537XbW26WLF-YzPQQ4OgM9WKz3FdGV30WLbIAp4U3WHE5Gdj

- https://safelifedefense.com/body-armor-guide/?srsltid=AfmBOorLn8dJWfY0w1nuj6xmxyaZidnSdYxll6okFLWBYUXZhDr1zMYu

- https://www.scuba.com/lists/heavy-duty-travel-bags?srsltid=AfmBOoozdotUCz-bZdzp6ipEpT-8JAT9llV-cmk5zpyNougBVRyqRAYE

- https://sewing-contractors.com/canvas-bags/

- https://vetopropac.com/tool-bags-for-extreme-conditions-gear-that-stands-up-to-weather-and-terrain/

- https://www.amazon.com/Rugged-Rhino-Large-Moving-Bags/dp/B0CLWBCPDG