Custom Rust-Resistant Tumblers: Corrosion‑Free Personalized Drinkware

A tumbler that resists rust is more than a convenience; it is the linchpin of a profitable on‑demand customization business. Returns from staining, metallic off‑tastes, or peeling prints erode margins and damage brand trust. As a mentor to founders launching print‑on‑demand and dropship drinkware lines, I’ve seen how choosing the right steel, the right finish, and the right personalization method reduces customer support tickets and lifts repeat purchase rates. This guide brings together reputable guidance on materials, corrosion science, and care practices, then translates it into practical buying and operational decisions for e‑commerce teams that sell custom, everyday carry drinkware.

What “Rust‑Resistant” Really Means

Rust resistance is not rust proof. Stainless steel protects itself by forming a thin, self‑healing chromium‑oxide film known as a passive layer. When chromium content is adequate and oxygen is present, this layer blocks oxygen and moisture from reaching the iron beneath. Authoritative explanations of this mechanism appear in stainless steel corrosion primers that emphasize how chlorides, heat, and low‑oxygen crevices can still defeat the passive layer and create pitting or staining (Splitflask blog). The common myth that “stainless never rusts” is incorrect, and magnetism has little to do with corrosion resistance. Even higher alloys can stain if abused or poorly maintained, which is why product care matters as much as material selection.

Real‑world corrosion often starts from two avoidable sources. The first is dissimilar metal contamination: flecks of carbon steel from scouring pads or tools can embed in a bottle’s interior and become a tiny rust seed in the presence of water and electrolytes. Using only stainless steel brushes and non‑abrasive tools avoids introducing free iron that kick‑starts corrosion (Ever Vessel). The second is moisture trapped under lids and gaskets after washing. Residual water drives both odors and corrosion; thorough air‑drying with lids disassembled addresses both issues (Ever Vessel). Stainless is best understood as “stain‑less,” not “stain‑proof.”

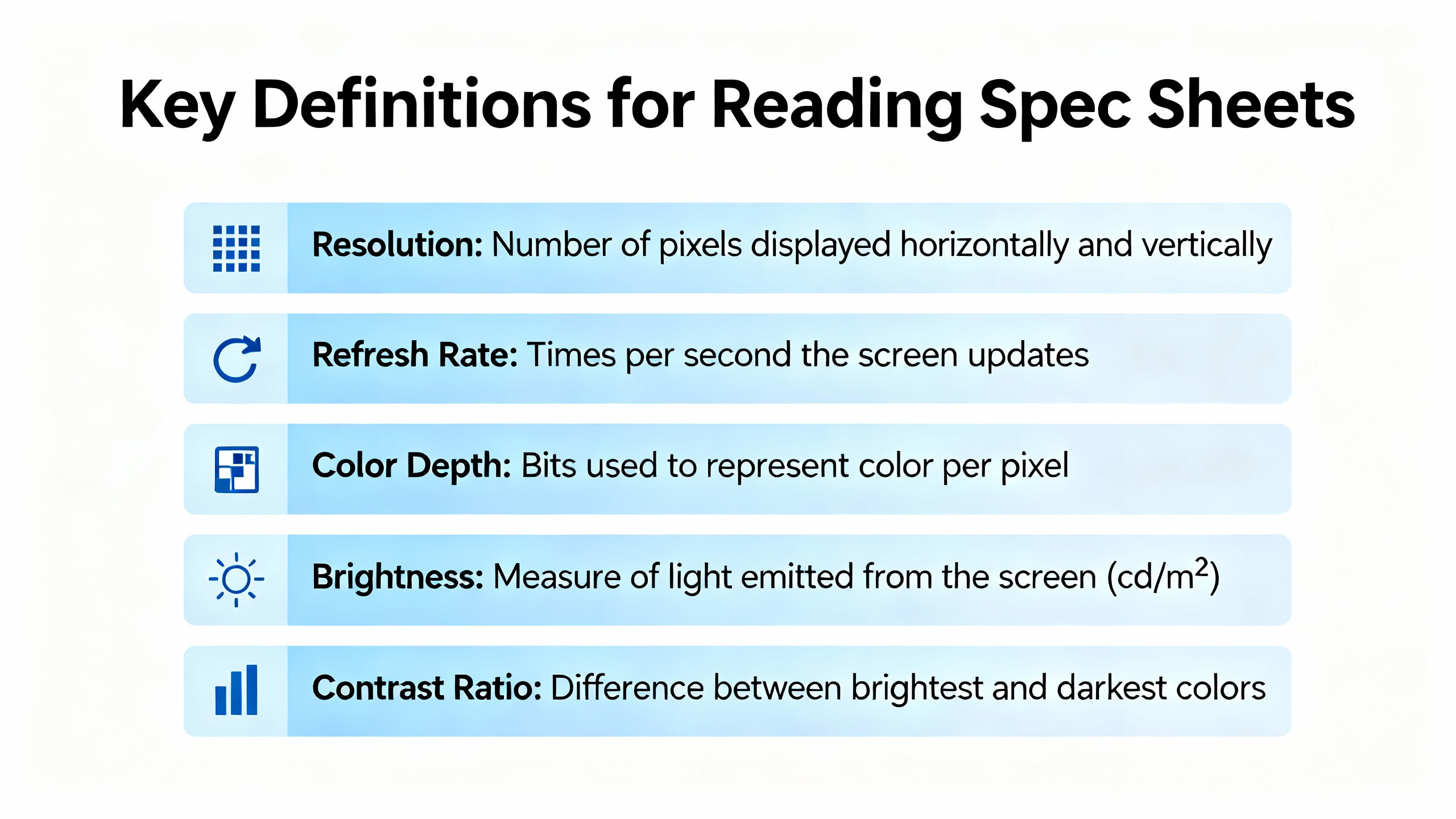

Definitions That Matter When You Read Spec Sheets

A few terms appear in every modern tumbler listing and they directly affect user experience, brand risk, and margin.

Double‑wall vacuum insulation means two stainless layers separated by a vacuum gap that dramatically slows heat transfer. This has become the gold standard for hot and cold retention, with many models maintaining comfortable temperatures across workdays, and some keeping iced water cold overnight according to independent tests and brand examples that cite hours‑long performance (Wirecutter; Water Bottle Advisor; Taste The Earth; CupsSupplier; Coolnice).

Grade 18/8 stainless is a food‑grade formulation widely used for tumblers. It is commonly associated with the 304 family and is highlighted by reputable product pages as both rust‑resistant and flavor‑neutral when properly maintained (First Mark; Coolnice; CupsSupplier; Taste The Earth). In e‑commerce listings, “18/8” is a quick proxy for quality and a safer bet than ambiguous “stainless” claims with no grade.

Powder‑coated finishes add color, grip, and a sweat‑free feel by reducing condensation. They can also protect the exterior from scuffs. When you personalize over powder coat, your choice of method determines durability and care requirements.

Laser engraving uses a beam to ablate the coating and reveal raw steel beneath. Reputable engravers emphasize that laser marks do not fade like some inks under routine use (First Mark). UV or wrap printing places color onto or within a protective layer. Tervis, for example, prints stainless exteriors and protects the image with a clear coat; for its classic clear tumblers it encapsulates a vinyl wrap between double walls and then heat‑seals it. File requirements, quality checks, and lead times are enforced to protect print outcomes and reduce rejects (Tervis).

Lids and gaskets control leak behavior, hygiene, and customer satisfaction. Top reviewers prefer lids with removable sliders and gaskets that can be disassembled for cleaning, plus gasketed straw ports to cut seepage. Most tumblers are splash‑resistant rather than fully leakproof, so encouraging upright use remains essential from both product page copy and customer education standpoints (Wirecutter).

Materials and Coatings For Corrosion‑Free Performance

Stainless steel dominates custom tumblers for good reasons. It is durable, inherently corrosion‑resistant, and, with vacuum insulation, keeps hot or cold for hours while staying comfortable to hold. Unlike some plastics, quality stainless is BPA‑free, does not leach, and will not shatter like glass in daily use (Dual Drinks; DiscountMugs; Everything Branded). If a metallic note bothers flavor‑sensitive coffee lovers, ceramic‑coated stainless places a thin ceramic layer between beverage and metal to minimize taste transfer while preserving the stainless shell’s durability and thermal performance (Dual Drinks; Taste The Earth). Glass provides the purest taste and is infinitely recyclable, but it is heavier and more fragile and better suited to desk use than trail or commute (Dual Drinks; Healthier Homes). For volume giveaways and tight budgets, BPA‑free plastics trade insulation for lighter weight and lower cost; they can retain flavors and scratch more easily than steel (Dual Drinks; Everything Branded). For a premium yet practical custom drinkware line with low return risk, insulated stainless—with or without ceramic lining—remains the most versatile base.

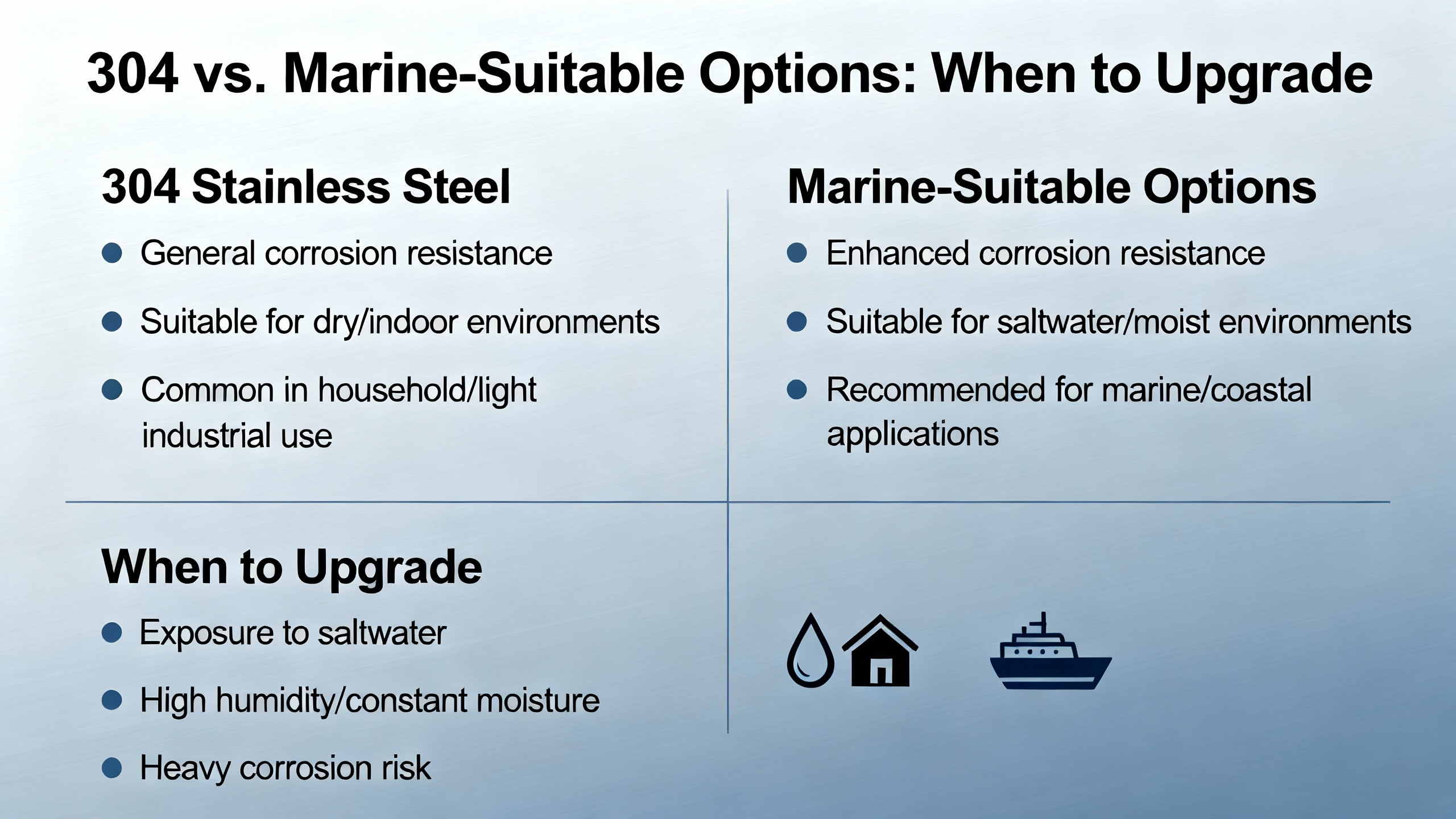

304 vs. Marine‑Suitable Options: When to Upgrade

Most customized tumblers you’ll see in the wild use 18/8 stainless associated with 304‑series steel. It is the mainstream choice for daily carry and corporate gifting. Some use cases justify a corrosion‑resistance upgrade, most notably coastal living, boating, and exposure to road salt or chlorinated pools. Marine‑oriented product pages promote tumblers built to endure splashes and salt air and specifically call out rust resistance in rugged environments (Custom Captain). Industry practice often steers coastal buyers toward marine‑suitable stainless because it handles chlorides better than basic formulations; this is an inference grounded in stainless selection norms for chloride exposure rather than a claim about a specific listing, and my confidence in this guidance is high. Even then, salt water still demands prompt rinsing and drying after exposure to preserve finishes and prevent crevice corrosion, which aligns with the broader corrosion mechanisms described by stainless education sources (Splitflask; Ever Vessel).

Personalization That Lasts Without Inviting Corrosion

The personalization method influences both customer delight and how the tumbler ages.

Laser engraving creates a crisp, permanent mark that will not peel and is favored for corporate identity that must endure dishwashing and rough bags. Because engraving exposes bare stainless where the powder coat is removed, the area still relies on the metal’s passive layer. Care instructions that emphasize rinsing and drying help that bare steel stay pristine over time. Powder‑coated bodies with laser engraving have become the promotional sweet spot thanks to toughness and brandable color ranges (First Mark; DiscountMugs).

UV or wrap printing excels at vibrant, full‑color graphics, seasonal capsules, and photo gifts. Process controls matter. Professional programs review files for minimum resolution, offer feedback on low‑quality uploads, and enforce approval timelines to prevent unhappy surprises—a best practice that reduces waste and rework in on‑demand workflows (Tervis). When selling dropship, note the care text: many printers recommend hand‑washing printed surfaces to preserve vibrancy, while some stainless bodies and certain lids are dishwasher safe; always default to the manufacturer’s guidance communicated on product pages (DHgate Smart; CupsSupplier; Wirecutter).

A concise comparison can clarify trade‑offs for your catalog and product pages.

Personalization Method | Durability in Use | Graphic Capability | Typical Care Guidance |

|---|---|---|---|

Laser engraving on powder coat | Very durable; mark does not fade | Monochrome mark revealing steel | Hand‑wash preferred for finish; engraving itself is robust |

UV or exterior print on stainless | Good with protective clear coat | Full‑color logos, photos, gradients | Often hand‑wash recommended to preserve color |

Encapsulated wrap (clear tumblers) | Protected between walls | Full‑color wraps | Body generally dishwasher safe; verify lid care |

Thermal Performance Without Sweat and Off‑Flavors

Thermal claims vary with size, wall thickness, lid design, and starting temperatures, but the pattern is consistent across reputable sources. Double‑wall vacuum stainless consistently outperforms plastics and glass for heat and cold retention. Product pages and tests report hot hold commonly in the half‑day range and cold hold stretching into a full day or more in some conditions. Examples include claims of roughly six hours hot and twelve hours cold for many 20–26 oz models (CupsSupplier; Coolnice; Taste The Earth) and independent observations that certain large tumblers keep iced water below comfortable sipping thresholds across 24 hours with or without added ice (Water Bottle Advisor). Sweat‑free exteriors are the norm for quality vacuum designs because the outer wall stays near ambient temperature, so condensation does not form. Taste management is primarily a care issue, not a materials flaw; stainless does not retain flavors when properly cleaned, and ceramic coatings further mute metallic notes for sensitive palates (Dual Drinks; Taste The Earth).

Care That Prevents Rust and Protects Prints

Care guidance is where many returns are won or lost. The underlying science is practical and simple.

Rinse immediately after acidic, sugary, or flavored drinks. Acids, chlorides, and sugars left to sit all attack cleanliness and the passive layer’s ability to self‑heal. After rinsing, wash with warm water and mild dish soap, disassemble lids and gaskets, scrub with a soft bottle or straw brush, and avoid bleach, harsh abrasives, and steel wool (DHgate Smart). If you must use a scourer, choose stainless tools only to avoid embedding free iron that later rusts (Ever Vessel). For stubborn odors or tea stains, a white vinegar soak for ten to fifteen minutes or an overnight hot‑water soak with a teaspoon of baking soda can break down residue and neutralize smells (DHgate Smart). Rinse thoroughly and air‑dry completely. Drying upside down with the lid off is the single most effective step for both odor control and rust prevention (Ever Vessel). Periodically deep‑clean, inspect seals for wear, and re‑seat gaskets in the correct orientation to prevent leaks.

An additional safety note appears in consumer guidance about vacuum‑insulated stainless: some brands seal the vacuum cavity with a small amount of lead‑based solder in the base, which is typically encapsulated. The risk is considered minimal unless the base plug is damaged, and lead‑free options exist for buyers who prefer them (Tasting Table). This is not a reason to avoid stainless altogether; rather, it is a reminder to inspect damaged items and to ask suppliers to disclose sealing methods when your brand’s safety stance requires it.

Buying Checklist for On‑Demand Printing and Dropshipping

Converting material knowledge into profitable catalog decisions requires a methodical checklist that balances customer experience with unit economics.

Start with the base vessel. For mainstream daily carry, pick 18/8 stainless steel with double‑wall vacuum construction and a powder‑coated exterior for grip and color. Check that lids are gasketed, disassemblable, and cup‑holder friendly, and describe leak behavior honestly as splash‑resistant unless the product is specifically rated leakproof with locking mechanisms. Test that lids can be fully taken apart for cleaning; reviewers and testing labs call out this detail as the difference between a fresh‑smelling tumbler and returns after a month (Wirecutter).

Choose the right capacity for your audience. Commuters and desk workers gravitate toward 20–30 oz for fewer refills. Outdoor hydration trends favor 32–40 oz with handled designs, while espresso and specialty beverages sit in the 10–16 oz band (Unifury; First Mark; Water Bottle Advisor). A clear mapping of capacity to use case pre‑empts refund requests when buyers discover their cup holder won’t fit a 40 oz cylinder. When in doubt, size up slightly is common shopping advice because you can fill a larger tumbler partway and still benefit from insulation; balance this against height, weight, and storage constraints in vehicles and strollers (Tasting Table; Wirecutter).

Plan for lead times, proofs, and file quality. Professional custom programs review designs and flag low‑resolution uploads. Minimums such as 480 by 480 pixels at 72 DPI and PNG for transparent backgrounds are common guardrails. Expect design approvals and production to ship in about six to eight business days for a mature program, with many laser engraving shops turning around approved orders in three to five business days; expedite shipping is often available, but build proof approvals into timelines, especially around gifting peaks such as Father’s Day, Thanksgiving weekend, and Christmas (Tervis; First Mark). Bulk buyers should expect discounts that improve above a dozen units and scale to large corporate orders, with common artwork formats accepted across engravers and printers (DiscountMugs).

Match personalization to the use case. For rugged daily carry and corporate identity, laser engraving on powder coat provides the best long‑term brand look with minimal care risk. For vibrant seasonal campaigns, use UV or encapsulated wraps and set accurate care expectations on the product page. Across methods, reinforce gentle hand‑washing for printed surfaces even when the stainless body itself is dishwasher safe, to preserve color saturation and finish integrity (DHgate Smart; CupsSupplier).

Calibrate pricing to value and logistics. Independent testing and buyer’s guides show that quality stainless tumblers often retail in the $35.00 to $57.00 band for 32–40 oz capacities, with perceived value driven by insulation, lid engineering, brand recognition, and finish quality (Water Bottle Advisor). Do not overspend for features your audience will not use; instead, message the two or three functional benefits customers care about most and back them with reputable rationale.

Capacity and Use‑Case Matching

Choosing sizes with intention simplifies fit, messaging, and inventory. The following table translates capacity into daily routines your PDP can speak to in plain language.

Capacity | Best For | Notes on Fit and Experience |

|---|---|---|

10–16 fl oz | Espresso, small coffee, tasting flights | Desk‑friendly, light; ideal for ceramic‑coated interiors and gift sets (Unifury; Taste The Earth) |

20–26 fl oz | Commute coffee, everyday iced drinks | Most cup‑holder‑friendly; common hot/cold claims around six and twelve hours respectively (CupsSupplier; Coolnice) |

30 fl oz | All‑day hydration, office to gym | Popular for laser engraving; sweat‑free powder coats; robust lid options (First Mark) |

32–40 fl oz | Outdoors, long drives, trend formats with handles | Check cup‑holder fit; more stable due to weight; retail price points trend higher (Water Bottle Advisor) |

Real‑World Scenarios and How to Decide

A commuter who alternates between hot coffee and iced water needs vacuum insulation, a tapered base, and a lid with removable slider parts that clean easily. Stainless with laser engraving avoids fading logos and protects brand perception on the go. A coastal boating customer benefits from a marine‑suitable stainless build with a flip or sliding lid that keeps spray out; product page copy should remind them to rinse with fresh water and dry promptly after salt exposure, which aligns with corrosion prevention best practices (Custom Captain; Ever Vessel; Splitflask). A corporate onboarding kit thrives on consistent colorways, sweat‑free powder coats that resist fingerprints, and engraving that matches brand standards across departments; bulk discounts and proofs ensure the identity is accurate and on time (DiscountMugs; PromoLeaf; Tervis). In each case, align material, finish, and personalization to the realities of the user’s day.

Common Misconceptions and Manageable Risks

Two misconceptions create outsized disappointment. The first is the belief that stainless can never rust. As corrosion primers explain, chloride‑rich environments, high heat, and neglected cleaning can overcome passivation and create pits or stains even on quality alloys (Splitflask). The second is that “leakproof” is a guaranteed trait for any lid marketed with a seal. Reviewers and testing labs emphasize that most tumblers are splash‑resistant, not leakproof, and tipping or shaking will cause seepage unless specific locking mechanisms are used and correctly engaged (Wirecutter). Clarity on your PDP reduces customer friction.

Two manageable risks are worth naming. Minor rust spots are usually low risk but signal that something in the care routine or tool choice has gone wrong; stop use, remove with a baking soda paste or vinegar, and adjust cleaning tools to stainless‑only bristles (Ever Vessel; DHgate Smart). As mentioned earlier, the presence of lead‑based solder encapsulated in some vacuum bases is a known industry practice; the hazard is minimized in intact products, and buyers who prefer to avoid it can choose options disclosed as lead‑free (Tasting Table). When in doubt, ask suppliers for documentation.

Sustainability and Brand Impact

Stainless steel’s durability, reusability, and recyclability anchor the sustainability case for premium tumblers. Higher production energy is offset by long service life, while reusables meaningfully reduce single‑use waste in daily routines (Dual Drinks; Everything Branded; PromoLeaf). Taste‑neutral materials and robust finishes increase the odds that customers actually reuse what you sell, which is the most important sustainability metric of all. One cited data point from a materials overview notes that a ceramic cup must be reused roughly thirty‑nine times to break even with disposable paper cups on energy consumption, a reminder that longevity and consistent use matter more than a single material label (Dual Drinks).

Takeaway

Rust‑resistant custom tumblers win when you combine the right base steel, smart personalization, honest claims, and clear care guidance. For most on‑demand catalogs, 18/8 vacuum‑insulated stainless with powder‑coated finishes and laser engraving delivers the best blend of durability, branding, and cost control. Ceramic‑coated interiors serve flavor‑sensitive segments, and marine‑suitable steel is a worthy upsell for salt‑exposed lifestyles. Educate customers on simple practices—no dissimilar metal scourers, rinse after acidic drinks, disassemble lids, and air‑dry thoroughly—and you will see fewer tickets and higher repeat rates. This is not just materials science; it is the operating system for a profitable, low‑friction custom drinkware line.

FAQ

Q: Are rust‑resistant tumblers truly rust‑proof for life? A: No. Stainless protects itself with a passive chromium‑oxide layer, but chlorides, heat, neglect, and dissimilar metal contamination can still cause staining or pits. With proper cleaning, thorough drying, and stainless‑only tools, real‑world rust can be prevented or minimized over long service lives (Splitflask; Ever Vessel).

Q: How do I remove small rust spots without damaging the finish? A: Start with mild approaches. Make a baking soda paste and gently rub the area with a soft cloth, or soak with white vinegar for ten to fifteen minutes and rinse thoroughly. Avoid steel wool and non‑stainless scourers that can deposit rust‑prone particles. Air‑dry completely and review your routine to prevent recurrence (DHgate Smart; Ever Vessel).

Q: Is ceramic‑coated stainless worth it for coffee? A: For flavor‑sensitive drinkers, yes. A ceramic lining reduces metallic taste while keeping stainless durability and insulation. Coatings can wear over many years, but for premium positioning and taste neutrality, it is a strong choice supported by drinkware material guides (Dual Drinks; Taste The Earth).

Q: Can I put custom tumblers in the dishwasher? A: Bodies made of quality stainless are often dishwasher safe, and many lids can go in the dishwasher if gaskets are removed. Printed exteriors may recommend hand‑washing to preserve color, while laser engraving on powder coat typically holds up well. Always follow the manufacturer’s care note on the PDP to set the right expectation (Wirecutter; CupsSupplier; DHgate Smart).

Q: What about lead in vacuum‑insulated bases I see discussed online? A: Some products use a small amount of lead‑based solder sealed in the base to close the vacuum cavity. Guidance suggests the risk is minimal unless that base plug is damaged; lead‑free designs are available if you prefer them. If safety policies require it, ask suppliers to confirm their sealing method (Tasting Table).

Q: Which steel should I choose for coastal living or boating? A: Marine‑suitable stainless is widely marketed for salt exposure and is the prudent choice if you expect regular contact with salt air or splashes. Rinsing with fresh water and drying promptly should still be part of the care routine. This recommendation reflects industry practice and product positioning in marine contexts; confidence is high based on that pattern (Custom Captain; Splitflask).

References

- https://www.tervis.com/create?srsltid=AfmBOoqRXMAXJUjEfRRpegNVeclBE6ilxqodZ8qCZ3p3fZWgycBkGj-R

- https://www.amazon.com/custom-tumblers/s?k=custom+tumblers

- https://www.coolnicetumbler.com/popular-custom-tumbler-products/

- https://smart.dhgate.com/essential-tips-for-properly-cleaning-and-maintaining-your-custom-stainless-steel-tumbler/

- https://www.discountmugs.com/category/stainless-steel-promotional-travel-mugs-and-customizable-tumblers?srsltid=AfmBOoqkpp8qXiMF3hpuOFNOpSUKSmVvtWaRbhQdXdMjXt00CY7jvDl3

- https://www.everythingbranded.com/blog/how-to-choose-the-perfect-material-for-your-custom-tumbler-a-comprehensive-guide

- https://firstmarkco.com/collections/custom-tumblers-personalized-insulated-drinkware-for-every-occasion?srsltid=AfmBOop9SEiY7xryQPWg2mE53uvfv4J5O1sGtkASZEzu1orAvuxmP9sX

- https://www.healthierhomes.com/post/safest-material-for-bottles?srsltid=AfmBOoqXTDLZ4PRXXhPRkg2HIAerJtK4ieQg_a1c6-D1AhKldI1gTlH2

- https://www.promoleaf.com/blog/tumbler-buyers-guide?srsltid=AfmBOoqnoIrXqCDZQ6xQsvKW4M7CS5l4JXx7MncDrQH1CfATAWKBJEHC

- https://thecustomcaptain.com/products/custom-30-oz-xl-insulated-tumbler?srsltid=AfmBOoo376x-XvbHvOcEqzcpwBzd4S-LF_XV-iFPOamclsN-_v4D3209