Quality Guaranteed Custom Items: Reliable Products You Can Trust

If you sell custom products with on‑demand printing or dropshipping, your brand promise lives or dies on the consistency of items customers unbox at home. Quality is not a nice‑to‑have; it is a profit lever and a trust engine. The American Society for Quality has long estimated the cost of poor quality at roughly 15–20% of sales, a number that includes rework, returns, support costs, and lost opportunities. In an on‑demand model where you may never physically touch the product, that cost compounds quickly through refunds, replacements, and churn. As a mentor who has helped dozens of founders scale from a handful of daily orders to peak season surges, I can tell you that the only sustainable “quality guarantee” is a system, not a slogan.

This article turns proven manufacturing quality practices into an e‑commerce playbook tailored for custom print sellers. You will learn the differences between quality control and quality assurance, what a workable quality system looks like when you do not own a factory, how to vet suppliers and keep them aligned, and how to use simple data discipline to reduce defects week by week. You will also get actionable buying and care tips grounded in reputable knowledge from organizations like ASQ, the Consumer Product Safety Commission, and Six Sigma practitioners, adapted for today’s on‑demand reality.

The Language of Quality That Every Seller Should Know

Quality control, quality assurance, and a quality management system are related but distinct. Quality control is about verifying outputs against defined specifications before the product reaches your customer. It includes inspections, testing, and acceptance criteria at the points where defects can be caught most efficiently. Quality assurance is preventive by design. It shapes the processes, inputs, training, and documentation so that defects do not occur in the first place. When you integrate both disciplines into a single set of policies, roles, and records, you have a quality management system, the operating backbone that standards such as ISO 9001 endorse. Industry resources from Six Sigma training providers and manufacturing educators emphasize that pairing preventive assurance with rigorous control is what lowers variation and lifts customer satisfaction.

Acceptable quality is not an abstract concept. Statistical Quality Control introduced the idea of acceptance sampling, where a defined sample of items is inspected to infer the quality of the whole lot. Six Sigma popularized data‑driven defect reduction, aiming for a benchmark of 3.4 defects per million opportunities. You do not have to chase that ideal to benefit from its mindset. A simple, documented process for setting specifications, sampling work in progress, inspecting pre‑shipment photos, recording defects, and feeding findings back into your supplier’s workflow will already put you ahead of most sellers. When issues arise, Corrective and Preventive Action (CAPA) closes the loop: identify the true root cause, correct the immediate symptom, and prevent recurrence by updating standards or training.

Regulatory and safety frameworks matter even in lifestyle categories. The CPSC urges brands to design out hazards before they ship, to control materials through the supply chain, and to keep records, lot controls, and recall plans. Having the right warning labels is not a substitute for eliminating foreseeable risks. For apparel, drinkware, toys, or home goods, this means clear material specifications, certificates where required, and packaging that protects the item through normal shipping conditions, not just ideal ones.

Why Guarantees Are Business‑Critical in On‑Demand and Dropshipping

Manufacturing teams know that quality protects brand reputation, reduces rework and scrap, and sustains compliance. Those benefits translate directly to e‑commerce economics. Every defective item you ship triggers a cascade of hidden expenses: replacement production, second shipping labels, customer support tickets, and the lifetime value you lose when a disappointed customer never comes back. ASC Software’s guidance on manufacturing quality control stresses that consistency and defect prevention protect reputation while managing costs; that same logic applies to print‑on‑demand because you are bound to supplier processes you do not fully control.

Digital tools make this more achievable for small teams. Deloitte reported that almost all manufacturers surveyed have begun digital transformation efforts. Cloud quality systems, digital checklists, and shared dashboards are now accessible without enterprise budgets, letting you specify requirements, track issues, and enforce change control as a lean brand. A data‑driven approach with simple charts and check sheets is enough to illuminate patterns in returns, late deliveries, and color mismatches so you can act decisively.

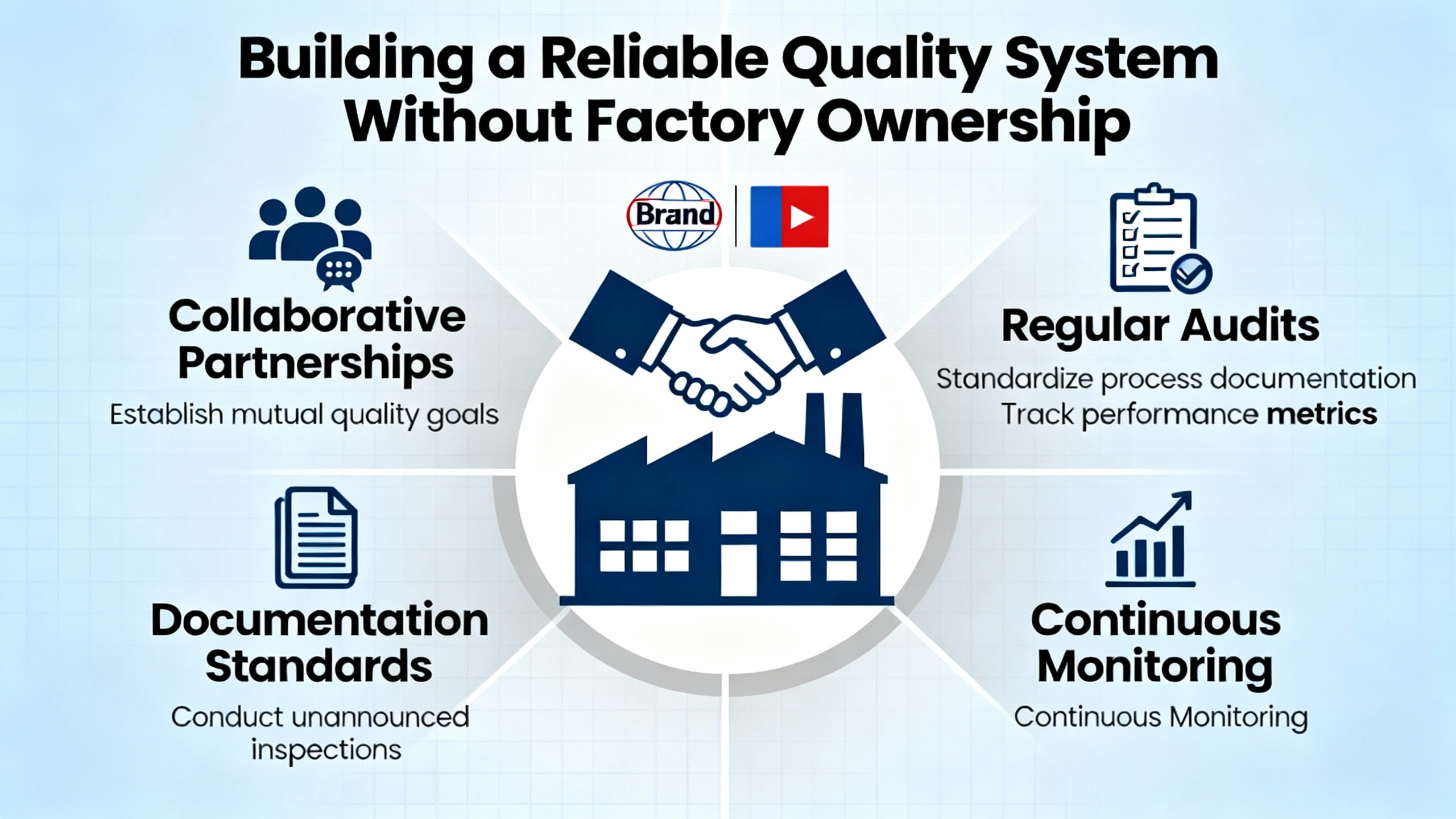

Building a Reliable Quality System When You Don’t Own the Factory

You can run a disciplined quality system even if production happens hundreds or thousands of miles away. In practice, your system rests on five pillars: clear specifications, dependable suppliers, proportionate inspection, reliable records, and continuous improvement. The details below reflect what works repeatedly for on‑demand sellers.

Practical Supplier Vetting, Onboarding, and Monitoring

Supplier quality management is not just procurement; it is strategy. Before you list a product, insist on a transparent bill of materials and process narrative that describes inks, substrates, coatings, and finishing. Request certificates of conformity where relevant. Ask for photos or recorded walkthroughs of critical steps so you understand where variation creeps in. Pilot with a small paid run across variations and ship those units to real addresses to observe packaging durability, barcode legibility, and scan events.

Onboarding is where you set expectations. Define the measurable attributes that matter for your category: garment size tolerances, print position and maximum shift, color accuracy by target values or approved references, ceramic gloss uniformity, seam straightness, or edge quality on wood and metal prints. Establish your acceptance criteria and review them line by line with the supplier. ComplianceQuest’s manufacturing best practices emphasize supplier performance tracking, risk assessment, and open collaboration; you may be a small account today, but a professional approach signals you are building a long‑term relationship grounded in performance, not haggling.

Monitoring should be lightweight but relentless. Track defect types by supplier and SKU. Review a few key indicators such as return rate, first‑pass yield where data is available, and complaint categories. Share monthly summaries and agree on the top one or two issues to fix next. Use a simple CAPA template to record the root cause, the corrective action, and the preventive change, then verify on the next cycle that the fix held. This cadence is how you compound reliability without micromanaging every job ticket.

Documenting Standards and Proofs Without Bureaucracy

Quality lives in documents people actually use. A one‑page product specification with photos and callouts beats a 30‑page manual no one reads. Define color references, artwork placement rules relative to seams or collars, acceptable print size ranges, and packaging and insert requirements. Keep controlled versions so every production team works from the latest issue. Document management systems, as highlighted by DocuWare, bring discipline to version control, training records, and audit trails. You do not need enterprise software to start; a shared folder with clear naming, an index, and a change log will carry you far if you enforce it.

Traceability is your insurance policy. Assign batches or production dates, and require those identifiers to appear on packaging or packing slips. If you ever need to isolate a defective set of units, traceability prevents over‑recalls and preserves margin. CPSC guidance also recommends recall readiness and rigorous recordkeeping; take that to heart even if your products are not subject to heavy regulation.

Sampling and Inspection That Fit On‑Demand Speed

You cannot hold every unit in your hands, but you can hold your process to account. Statistical acceptance sampling allows you to inspect a subset and infer lot quality. Use proportionate sampling for routine runs, and escalate to more thorough checks when you change materials, print methods, or factories. For safety‑critical elements such as child‑related components or items that contact food and drink, layer additional controls. CPSC’s safety‑by‑design principle is clear: eliminate the hazard first, then guard, then warn. That hierarchy applies to drinkware coatings, toy attachments, and anything that could become a choking or ingestion hazard.

Pre‑shipment photo verification is a practical control for remote sellers. Require wide shots for placement, close‑ups for print sharpness and color rendition, and packaging photos that show cushioning, corner protection for framed prints, and label placement. Maintain a simple check sheet so inspectors and account managers evaluate the same criteria every time. Consistency in the inspection routine is as important as the inspection itself.

Packaging, Shipping, and Transit Protection

Logistics damage feels like a random tax on your business until you design it out. SafetyCulture’s quality control guidance highlights stress‑testing and clear shipping requirements to prevent transit damage. For breakable items, specify corner protectors, tested cushioning layers, and robust outer cartons. For seasonally temperature‑sensitive adhesives or inks, define handling notes and durations. Add scannable identifiers on cartons so your support team can match customer complaints to a batch quickly.

What you require, you must verify. Periodically order products to varied addresses and climates. Track the condition of the packaging and the product upon arrival. Use those observations to tighten your packaging SOP and update supplier instructions. This small investment pays back when peak season volumes expose weak points in materials or fulfillment.

Data‑Driven Continuous Improvement for Sellers

A few simple tools can transform a chaotic returns inbox into a roadmap. Statistical Process Control charts track whether a metric such as return rate or misprint rate is fluctuating within expected bounds or drifting. Pareto analysis helps you focus on the “vital few” causes that drive the majority of complaints, such as a specific fabric color, a particular mug style, or one print size. Check sheets are structured tallies that team members use to record defect types consistently, turning anecdotes into data you can act on. Manufacturing sources like MachineMetrics and Six Sigma training emphasize these general‑purpose tools because they are easy to teach and powerful in practice.

Here is how to translate classic quality tools into an on‑demand context without heavy software or headcount.

Quality Tool | How a POD Seller Uses It | Outcome |

|---|---|---|

Control charts | Plot weekly return rate per SKU and per supplier to spot drifts after a material or process change | Early detection, faster containment |

Pareto analysis | Rank the top reasons for returns in the past 30 days to direct supplier action on the biggest issue | Focused improvements with measurable impact |

Check sheets | Standardize how support and QA label defects such as color deviation, placement shift, or damage on delivery | Comparable data across weeks and teams |

CAPA | For a recurring misprint, document root cause, the immediate fix, and the preventive change in artwork preflight or machine settings | Reduced repeat defects and institutional memory |

You do not need complex dashboards to begin. A spreadsheet with dates, SKUs, suppliers, issue categories, and counts is enough to populate a Pareto chart and catch trends that intuition misses.

Practices That Make Guarantees You Can Keep

Quality guarantees are not marketing copy; they are service level agreements with your customers, backed by operations and finance. The best guarantees are specific, fair to both sides, and supported by your quality system. Define what counts as a quality issue, how customers can report it, what evidence you require, and how quickly you will resolve the case. Document acceptable remedies such as replacement, refund, or store credit, and track your response times.

Care guidance reduces avoidable returns. For apparel, include a brief care card and product page guidance in plain language to help customers preserve print longevity and fabric integrity. For ceramics and drinkware, specify handling expectations in line with your material and coating choices. The role of the guarantee is not only to make things right but also to equip customers to use items correctly.

Regulatory readiness is part of keeping promises. CPSC advises brands to monitor the market, document compliance efforts, and be recall‑ready with lot controls. Even if your category faces minimal regulation, adopting this discipline protects you from outsized risk. Documentation is your ally in resolving disputes with suppliers and marketplaces because it shows reasonable efforts and clear standards.

Pros and Cons of Common Quality Approaches for Custom Products

Every control method has trade‑offs. Understanding those trade‑offs helps you design a system that fits your product mix, order volume, and risk profile.

Approach | Strengths | Trade‑offs |

|---|---|---|

100% inspection | Maximum confidence for critical attributes and launches | Higher cost and slower cycle times; subject to inspector fatigue |

Acceptance sampling | Balanced cost and assurance; scalable for steady volumes | Requires statistical discipline; residual risk remains |

Supplier certification and audits | Preventive, culture‑building; improves outcomes upstream | Upfront time investment; results depend on supplier engagement |

TQM and continuous improvement | Compounds gains across people, process, and tech | Requires leadership commitment and sustained data habits |

Drawing from manufacturing practices described by Six Sigma educators and quality platforms, the most resilient sellers blend these approaches. For new SKUs, inspect more; for stable runners with a strong track record, sample proportionately. Across the board, strengthen supplier relationships and use CAPA to lock in gains.

Buying Tips for Store Owners Sourcing Custom SKUs

Clarity before commitment saves money later. Distinguish the attributes your customers will pay for from cosmetic or hidden features that add cost without value. Factored quality resources call this difference essentials versus nice‑to‑haves, and they encourage setting measurable testing benchmarks before production. Translate that mindset into your product briefs: call out the materials and print methods that matter, define tolerances that customers notice, and give your partner a target to hit.

Sample deliberately. Order several variants across sizes and colors. Evaluate them under natural light and artificial light so you understand perceived color differences. Run a short use test when relevant, such as washing apparel a few cycles or handling drinkware repeatedly, and observe the outcomes. You are not running a lab; you are validating that the item performs as customers expect. Keep notes and photos because those become your reference set.

Negotiate quality terms with data. Share your acceptance criteria and the defect categories you will track. Agree on remedies for confirmed issues and how you will present evidence. Explain that you will conduct periodic reviews and highlight one priority at a time, so your feedback is actionable. Quality teams in manufacturing emphasize that open communication and trust with suppliers enable faster, more durable fixes than adversarial exchanges.

Mind safety and compliance as you buy. CPSC guidance stresses safety by design, standards awareness, and supply chain control. For children’s items, food contact products, or anything that could present a safety hazard, request and archive relevant certificates and test results. Build these requirements into your vendor selection process rather than treating them as afterthoughts.

Handling Defects and Customer Complaints with Grace and Evidence

When an issue surfaces, speed and clarity set the tone. A support playbook that defines what to ask for, how to triage, and how to respond keeps customers confident and teams consistent. SafetyCulture highlights the value of a clear playbook and the importance of tracking recurring issues so they can be fixed at the source. Once you confirm a defect, choose the remedy that serves both the customer and the business. Replacement is often the right answer when the product still fits the customer’s need; refunds may be better when the experience is compromised or time‑sensitive events have passed.

Internally, treat each resolved case as data. Categorize it accurately, update your charts, and decide whether it warrants a CAPA. If the issue repeats, escalate with your supplier and share the pattern with evidence. Verify the fix on subsequent orders. Over time, your complaint data becomes a map of how your products and partners are improving.

Future‑Proofing Your Guarantee with Smart Technology

The direction of travel in quality management is clear. Manufacturers are integrating real‑time monitoring and analytics into everyday operations. AI and machine learning are augmenting trend detection and decision support. Deloitte’s research shows that digital investment is nearly universal among manufacturers now, and tools have become accessible for small businesses. For a lean e‑commerce brand, this can be as simple as automating data capture from your store and support platform into a shared dashboard, or as structured as adopting a cloud quality system to manage documents, audits, and training, as document management providers describe. As you scale, these capabilities let you maintain standards across more suppliers, more SKUs, and more orders without adding noise to your team.

The trick is to start with the basics and layer sophistication. A documented spec, a sampling plan, a returns chart, and a monthly review will already reduce your defect rate. When those habits stick, add automation and integrations. Continuous improvement programs such as Total Quality Management thrive in environments where leaders set clear quality objectives and employees have the tools and data to meet them.

Frequently Asked Questions

How can I “guarantee quality” when I never touch the product?

Run your guarantee through your system rather than your hands. Establish clear acceptance criteria and require pre‑shipment photos for critical attributes. Use acceptance sampling to inspect proportionately and escalate checks when suppliers change materials or processes. Keep records and lot identifiers, and use CAPA to resolve recurring issues. These practices, common in manufacturing quality literature, adapt well to on‑demand workflows.

What defect rate should I target in custom printing?

Six Sigma literature popularized the ideal of 3.4 defects per million opportunities, which is an aspirational benchmark. Your target should align with your category, price point, and customer expectations. Start by baselining your current rates, focus on the top issue through Pareto analysis, and drive it down with CAPA. As your system matures, you can tighten standards without overburdening suppliers or slowing cycle times.

How should I prepare for peak season without sacrificing quality?

Lock your specifications by early fall, pilot any new SKUs at least a few weeks before sales events such as Black Friday and Cyber Monday, and run packaging checks under real shipping conditions. Share a clear surge plan with suppliers, including expected volumes and quality priorities. Maintain your sampling and photo checks; do not suspend controls just because volumes rise.

Closing

A quality guarantee is not a promise to be perfect; it is a commitment to design out problems, detect what slips through, and make customers whole with speed and grace. The playbook manufacturers use—clear standards, proportionate inspection, disciplined records, and continuous improvement—works just as well for on‑demand e‑commerce. Start lean, measure what matters, and strengthen one control at a time. When you do, your guarantee shifts from a liability line to a growth moat.

References

- https://www.cpsc.gov/business--manufacturing/business-education/business-guidance/BestPractices

- https://blog.qasource.com/top-software-qa-challanges

- https://www.appsierra.com/blog/how-to-maintain-the-quality-of-product

- https://www.browserstack.com/guide/challenges-faced-by-qa

- https://www.factoredquality.com/resource/8-best-practices-to-increase-quality-control-in-manufacturing

- https://www.fastcompany.com/91219457/11-brand-strategies-to-ensure-product-and-service-quality-control

- https://www.globalapptesting.com/blog/challenges-in-qa-testing

- https://www.machinemetrics.com/blog/quality-control-in-manufacturing

- https://momentic.ai/blog/solving-quality-assurance-issues

- https://www.newcastlesys.com/blog/common-quality-control-issues-and-how-to-avoid-them